Meeting International Standards: IPF and FIP Compliance for Padel Courts

Official Padel Court Dimensions and Layout per IPF and FIP Regulations

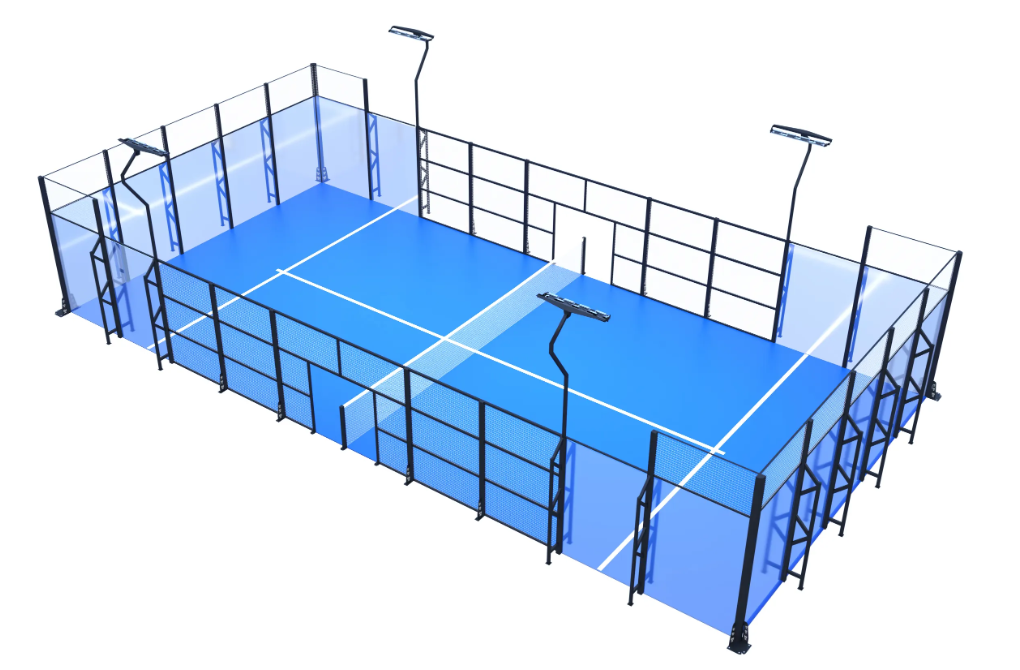

Padel courts at the professional level need to follow specific rules set by governing bodies like FIP and IPF. Courts are generally around 20 meters long by 10 meters wide, give or take about half a percent. There's also a service line placed approximately 6.95 meters away from the net. When it comes to the side walls, they start with 3 meter high glass panels right next to the net area. These panels get progressively shorter as we move towards the back of the court, dropping down to just 2 meters tall. This design isn't random either it helps control how balls bounce off the walls during matches, which makes all the difference when players are competing at top levels.

Structural Requirements for Certified Competition-Ready Courts

Courts that comply with standards typically feature tempered safety glass walls at least 12mm thick along with powder coated steel frames for durability. When it comes to shock absorbing turf surfaces, they need to hit a minimum of 50% vertical deformation according to FIP requirements just to reduce the chance of injuries happening. For outdoor setups, concrete bases are necessary with a gentle slope between 1% and 2% so water doesn't pool up on the surface. Another important aspect for certified facilities is ensuring spectators can see around the entire court area thanks to transparent enclosures and special anti glare treatments applied to the glass panels.

Role of Certification in Ensuring Quality and Playability

Getting third party certification means every part of the court setup, including those wall anchors and even the line markings, must follow FIP's detailed specs which run across 86 pages in their latest version from 2022. The numbers don't lie either - facilities that skip this IPF validation tend to see surfaces wearing down about 37% faster over just one year, as shown by research conducted at racquet sports centers back in 2023. On top of initial approval, certified courts need regular checks too. Structural welds get looked at once a year, along with measuring net tension which should be around 88 cm in the middle spot and stretch out to about 92 cm towards each end. They also test how well enclosures hold up against impacts. All these ongoing assessments help keep playing surfaces ready for competition standards throughout the season.

By prioritizing FIP/IPF compliance, padel court manufacturers demonstrate their commitment to global interoperability and long-term performance—key factors for clubs hosting international tournaments.

High-Performance Materials in Padel Court Construction

Modern padel courts require materials that balance playability, safety, and longevity. The choice of construction components directly impacts player experience and maintenance costs over the court’s lifespan.

Playing Surfaces: Artificial Grass, Concrete, and Carpet Options

Courts use three primary surface types:

- Artificial grass (8–12 mm pile height) delivers consistent ball bounce and reduces joint stress during lateral movements

- Concrete surfaces coated with acrylic or polyurethane enable faster gameplay ideal for competitive environments

- Carpet systems with silica sand infill enhance traction while maintaining efficient drainage

Each surface type requires proper sub-base preparation and secure perimeter anchoring to prevent shifting during intense play.

Walls and Enclosures: Tempered Glass, Steel Frames, and Mesh Fencing

The standard enclosure integrates:

- 10–12 mm tempered glass panels (lower walls) for reliable ball rebound and clear spectator views

- Galvanized steel frames with corrosion-resistant powder coating

- 3–4 mm mesh fencing (upper sections) to contain high shots while promoting airflow

These materials endure repeated ball impacts exceeding 110 km/h without warping or degradation.

Material Durability Under Indoor and Outdoor Conditions

UV-stabilized polymers in outdoor surfaces resist fading, while indoor carpet systems include antimicrobial treatments to prevent moisture damage. Glass panels are thermally tempered to withstand temperature fluctuations from -20°C to 50°C. Leading manufacturers conduct accelerated weathering tests simulating over 10 years of environmental exposure during quality control.

A trusted padel court manufacturer will specify material load ratings, impact resistance scores, and climate-specific maintenance protocols tailored to your facility’s usage patterns.

Engineering Excellence: Foundations and Structural Integrity

Trusted padel court manufacturers prioritize structural integrity through rigorous geotechnical planning and site-specific adaptations. A 2023 study by the International Construction Standards Institute found that 73% of foundation-related failures in sports facilities stem from inadequate soil analysis during site preparation.

Geotechnical Planning and Site Preparation for Stable Foundations

Engineers perform comprehensive soil tests to assess load-bearing capacity, moisture content, and compaction needs before pouring foundations. For outdoor installations, drainage patterns are evaluated to prevent water pooling and subsurface erosion. Indoor projects include vapor barrier installation and slab elevation adjustments to combat humidity-related concrete deterioration.

Indoor vs. Outdoor Construction: Key Structural Differences

Outdoor padel courts require UV-resistant tempered glass (minimum 12mm thickness) and galvanized steel frames capable of withstanding wind loads up to 130 km/h, while indoor designs emphasize acoustic insulation and ventilation. Thermal expansion gaps—typically 10–15mm between components—are calibrated differently for temperature-controlled arenas versus open-air facilities.

All compliant systems follow ISO 9001-certified welding protocols and meet ASTM F2152 material durability standards, ensuring consistent performance across environments.

Precision Build and Quality Control: Safety, Accuracy, and Finish

Trusted padel court manufacturers apply precision engineering throughout construction to meet performance and safety benchmarks.

Ensuring Flush Walls, Accurate Line Markings, and Consistent Surfaces

Laser-guided alignment ensures wall alignment within ±2mm of IPF-certified dimensions, while digital templating maintains line markings within 1.5% tolerance of official standards. Multi-layer surface compression techniques ensure uniform ball bounce across all zones, crucial for professional-level play.

Safety Standards in Padel Court Manufacturing and Installation

Galvanized steel frames undergo 8-point structural stress tests to withstand triple the standard wind loads. Tempered glass walls (minimum 4mm thickness) absorb high-velocity impacts without shattering. Rounded corner caps and anti-slip turf adhesives reduce player injury risks by 40% compared to non-certified designs, according to the Sports Surface Safety Council (2023).

Choosing a Trusted Padel Court Manufacturer: Expertise and Long-Term Value

Evaluating Manufacturer Credentials, Experience, and Client Portfolio

When looking for a certified padel court manufacturer, there are several key factors to check first. The company should follow FIP/IPF standards, have a solid track record of past projects, and demonstrate real expertise in this specific area. According to data from the Global Court Construction Report released last year, manufacturers who've been around for more than a decade tend to produce courts with about 37 percent fewer structural issues after five years compared to those just starting out. That's quite a difference when considering long term maintenance costs. Take time to look through their portfolio too. Make sure they've actually built courts similar to what you need whether it's something for a municipal complex, private club setup, or commercial sports center. Seeing actual examples helps determine if they can handle different situations effectively.

Balancing Cost, Quality, and Compliance in Contractor Selection

Premium materials such as tempered glass walls or UV resistant artificial turf definitely come with bigger price tags initially, but they actually save money over time. Studies from the Indoor Sports Infrastructure Report back in 2022 found these materials cut down on lifetime costs somewhere between 19% to 26%, mainly because they need less maintenance work and last much longer than cheaper alternatives. When shopping around for suppliers, it's worth looking at companies that give clear details about their pricing structures and stick to IPF certified standards. Avoid businesses that try to cut corners by using materials that don't meet proper specifications, even if their prices look tempting at first glance.

Long-Term Maintenance Support and Warranty Offerings

Top manufacturers typically offer structural warranties lasting around 10 years along with yearly maintenance packages that handle things like fixing surfaces, checking anchors, and preventing rust buildup. These services become really important when dealing with outdoor courts since they face constant exposure to moisture and changing temperatures throughout the seasons. Facility managers should double check what their warranty actually covers because many have run into surprise charges after installation. A recent survey from Sports Venue Management found that about 42 percent of respondents faced unexpected costs down the road, which can eat into budgets without warning.

FAQ

What are the standard dimensions for a professional padel court?

Professional padel courts are generally around 20 meters long by 10 meters wide, with a service line placed approximately 6.95 meters from the net.

Why is certification important in padel court construction?

Certification ensures that every aspect of the court, from wall anchors to line markings, meets FIP's detailed specifications, promoting quality and playability.

What types of playing surfaces are used in padel courts?

Padel courts can have artificial grass, concrete, or carpet surfaces, each offering unique benefits such as consistent ball bounce or enhanced traction.

What materials are used for padel court walls and enclosures?

Padel courts typically use tempered glass for lower walls, galvanized steel frames, and mesh fencing for upper sections.

What should I consider when choosing a padel court manufacturer?

Look for manufacturers with a strong track record, compliance with FIP/IPF standards, and a history of successful projects in various settings.

Table of Contents

- Meeting International Standards: IPF and FIP Compliance for Padel Courts

- High-Performance Materials in Padel Court Construction

- Engineering Excellence: Foundations and Structural Integrity

- Precision Build and Quality Control: Safety, Accuracy, and Finish

- Choosing a Trusted Padel Court Manufacturer: Expertise and Long-Term Value

-

FAQ

- What are the standard dimensions for a professional padel court?

- Why is certification important in padel court construction?

- What types of playing surfaces are used in padel courts?

- What materials are used for padel court walls and enclosures?

- What should I consider when choosing a padel court manufacturer?