The Global Rise of the Padel Court Factory and Its Role in Sports Infrastructure

How the Padel Court Factory Became a Cornerstone of Modern Sports Development

Padel court manufacturing has really taken off alongside the sport itself, which has grown at lightning speed. We're talking about around 25 million people playing regularly all over 90 different countries according to The Upside Sports report from last year. These production facilities have become essential parts of how cities build their sports infrastructure nowadays. City planners and business folks love including padel courts in their projects because they take up so much less room compared to regular tennis courts. A factory made padel court needs about 40 percent less space actually. That makes sense for places where land is expensive or hard to come by. We see this happening everywhere now, whether it's fancy new complexes in Dubai or simple setups in public parks throughout Stockholm. Padel seems to be breaking down barriers when it comes to access to racket sports, something that wasn't really possible before.

Global Demand Driving Innovation in the Padel Court Manufacturing Process

Record-breaking court installation rates—40,000+ global courts with 26% annual growth—have forced manufacturers to reengineer production workflows. Leading factories now employ:

- Modular Design Systems: Pre-assembled components reduce on-site installation time by 60%

- Climate-Adaptive Materials: Coatings that withstand -30°C to 50°C temperature extremes

- AI-Powered Quality Assurance: Computer vision systems inspecting 200+ weld points per court frame

The UK's 116% year-over-year court expansion (2022–2023) exemplifies how regional demand surges catalyze manufacturing breakthroughs, particularly in weather-resistant court designs for northern European markets.

Inside the Padel Court Manufacturing Process: Design, Automation, and Quality Control

Initial Design and CAD Modeling in the Padel Court Factory

The production process kicks off with design meetings where engineers work hand-in-hand with architects and folks who know sports inside out. Using advanced computer modeling tools, they create detailed 3D representations that show how balls will fly through the air, where players tend to move on the court, and where different materials might start showing signs of wear. These virtual mockups let teams tweak things like court size, adjust the angle of those glass walls, even dig deeper into foundation requirements all without touching a single piece of actual construction material. This approach cuts down on wasted resources while making sure everything performs exactly as intended when it finally gets built.

Precision Cutting and Framing: The Role of Automation in the Padel Court Manufacturing Process

CNC machines guided by CAD models cut steel framing components with ±1.5 mm accuracy—critical for seamless court assembly. Robotic welders assemble prefabricated wall sections using automotive-grade techniques, while automated surface grinders prepare concrete footings to within 0.2° of levelness, eliminating manual errors that historically caused delays.

Quality Control Checkpoints During Production

Nine inspection stages verify:

- Material tensile strength (tested to 750 N/mm²)

- Glass wall transparency (≥92% light transmission)

- Welding seam integrity (ultrasonic tested)

Third-party inspectors validate compliance with FIP (International Padel Federation) standards at three production milestones before approving shipments, ensuring structural and safety benchmarks are met.

Timeframe From Order to Completion in a Standard Padel Court Factory

The average time needed to build a standard sized court measuring around 10 meters by 20 meters is roughly between 28 and 35 days once the design gets approved until it's ready for packaging and shipping out. When clients want special colors or different measurements than usual specifications, this can actually push back the timeline by another week or so. These days most manufacturers rely on automated scheduling software that keeps track of when materials arrive at the factory floor. For instance, steel coils typically show up within three days after ordering. This kind of coordination cuts down waiting periods significantly. According to data published in the latest report from the International Padel Federation in 2023, factories using these systems save about 40 percent off their traditional production schedules which required people to manually organize everything themselves.

Core Materials in Padel Court Construction: Durability, Performance, and Sustainability

Artificial Grass Surfacing: Technology and Maintenance in Padel Court Construction

Factories today are turning to synthetic turf made with UV stabilized polyethylene fibers because it strikes a good balance between consistent ball bounce around 6 to 8 cm pile height and maintaining proper player traction on the field. The backing systems have come a long way too, featuring lots of tiny holes that let water drain super fast over 200 liters per square meter each hour according to some tests. Another big improvement is antimicrobial coatings which cut down on cleaning expenses roughly 30 percent when compared to older turf versions as noted in the Sport Surface Tech Report from last year. Regular maintenance still matters though regular brushing once a month plus adding fresh sand every year keeps those fibers aligned properly and maintains decent shock absorption properties for athletes.

Reinforced Concrete Foundations and Their Long-Term Stability

Steel-reinforced concrete slabs (25–30 cm thickness) form the base, with vibration-compacted aggregates ensuring <2 mm/m² surface deviation. Moisture sensors embedded during pouring detect curing anomalies, contributing to 50+ year lifespans even in freeze-thaw cycles. A 2023 engineering study showed these foundations withstand 8.5 kN/m² dynamic loads without subsidence—essential for high-traffic facilities.

Tempered Glass Walls and Structural Integrity Standards

Safety-tempered glass panels (10–12 mm thickness) undergo heat treatment at 650°C followed by rapid cooling, increasing impact resistance by 400% versus standard glass. Every batch is tested to EN 12600 safety standards, ensuring containment of 150 g balls at 120 km/h. Laminated edge bonding prevents microfracture propagation, even after 10,000+ simulated ball strikes.

Metal Mesh Fencing and Weather-Resistant Coatings

Galvanized steel mesh (3–4 mm wire diameter) receives triple-layer powder coatings (epoxy primer, polyester midcoat, polyurethane topcoat), providing resistance equivalent to 25 years of coastal exposure in salt spray tests. Modular clamp systems allow tension adjustments, maintaining <5 mm panel gap tolerances across temperature fluctuations from -30°C to 50°C.

Sustainability Considerations in Material Selection

Seventy percent of leading padel court factories now incorporate recycled steel in structural components, while artificial turf contains 35–40% post-consumer plastics. Carbon footprint analyses show modern production methods reduce embodied energy by 22% compared to 2018 baselines, with ISO 14001-certified plants achieving 90% material utilization through precision cutting algorithms.

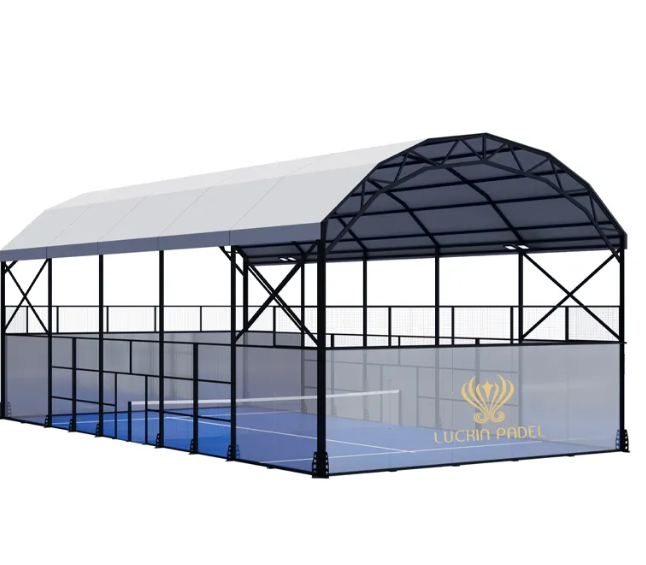

Modular and Prefabricated Padel Court Designs: Enabling Fast, Scalable Deployment

Advantages of Modular Padel Court Designs in Urban and Remote Locations

Modular designs really help solve those pesky space problems in crowded cities and the tough logistics folks face in rural spots. They work because everything is made in factories with standard parts. Take urban sports centers for instance. These places often struggle with tiny spaces. But with modular setups, they can fit way more onto their property. Some rooftop installations alone handle over 150 players each week. And out in remote areas? Modular courts come together nicely even when there's no flat ground around. We've seen them pop up on floating docks that would normally stop construction dead in its tracks. The manufacturers we talk to mention something interesting too. Their transportation bills drop about 40% compared to regular building methods. Why? Because these pre-made pieces pack so much better during shipping.

How Prefabricated Padel Court Designs Reduce Installation Time by Up to 60%

Factory production of pre-tested modules eliminates on-site welding, painting, and curing delays. Automated alignment systems enable crews to install a full court in 3 days instead of 8—a 63% reduction confirmed by 2024 construction analytics. Electrical conduits and drainage channels arrive pre-integrated, while modular innovations like interlocking glass panels prevent weather-related setbacks.

Case Study: Installing a Prefabricated Court in 72 Hours

A coastal resort deployed a competition-grade padel court during peak season using prefab methods:

- Day 1: Laser-leveled foundation pads and assembled steel frame

- Day 2: Installed tempered glass walls with automated crane placement

-

Day 3: Surface finishing and IoT sensor calibration

The $92k project generated $18k in bookings within the first month, achieving 79% faster ROI than conventional builds.

Customization Options Within Modular Systems

Leading manufacturers offer:

- Surface variations: Shock-absorbent acrylic vs. tournament-grade artificial grass

- Lighting configurations: 300–800 lux LED arrays with motion sensors

-

Branding integration: Printed court lines and sponsor panel slots

This flexibility supports 93% of clients who require multi-use facilities for events, training, and recreational play.

Innovation and Quality Assurance in China’s Padel Court Factories

Integration of IoT sensors for real-time structural monitoring

Top manufacturing plants are now putting IoT sensors right into sports court structures while they're being built, so these facilities can monitor structural stress and environmental effects around the clock. The sensor systems actually catch those tiny shifts happening in glass panels and check how solid the foundations remain over time, sending all this information to maintenance software that predicts problems before they happen. According to research published last year in the Global Sports Infrastructure Journal, stadiums and arenas with these smart court systems saw a drop of about two thirds in reported structural issues when compared against older buildings without such technology. That's pretty impressive for something most people never even notice when walking onto a court surface.

Third-party certifications and compliance with international padel federation standards

Every production batch undergoes rigorous testing against FIP safety and performance benchmarks. Factories maintain ISO 9001 certification and use blockchain-based material tracing to verify supply chain compliance. Independent audits reveal a 41% improvement in standard adherence since 2021, with most facilities exceeding minimum impact-resistance requirements by 15–20%.

Worker training and automation balance in the manufacturing process

Advanced CNC cutting systems work alongside technicians trained in composite material science through factory-sponsored apprenticeship programs. This hybrid approach automates repetitive tasks while preserving artisan-level quality checks. Manufacturers report a 28% productivity gain (SportsTech Analytics 2023) without compromising the hand-finished tolerances required for tournament-grade courts.

FAQ Section

What is driving the popularity of padel courts?

The popularity is driven by the sport’s global growth, requiring less space than traditional sports facilities, and the accessibility it provides to players in various locales.

How do padel court factories ensure quality?

Quality is ensured through rigorous inspections across nine production stages, third-party certification, and compliance with international standards.

What materials are used in padel court construction?

Key materials include UV-stabilized synthetic turfs, reinforced concrete, safety-tempered glass, and galvanized steel mesh with weather-resistant coatings.

How quickly can a padel court be installed?

Prefabricated and modular padel court designs allow for installation times reduced to as little as 72 hours, depending on the project scope.

Are padel court designs customizable?

Yes, modular systems allow for extensive customization options including surface types, lighting configurations, and branding integration to suit various client needs.

Table of Contents

- The Global Rise of the Padel Court Factory and Its Role in Sports Infrastructure

- Inside the Padel Court Manufacturing Process: Design, Automation, and Quality Control

-

Core Materials in Padel Court Construction: Durability, Performance, and Sustainability

- Artificial Grass Surfacing: Technology and Maintenance in Padel Court Construction

- Reinforced Concrete Foundations and Their Long-Term Stability

- Tempered Glass Walls and Structural Integrity Standards

- Metal Mesh Fencing and Weather-Resistant Coatings

- Sustainability Considerations in Material Selection

- Modular and Prefabricated Padel Court Designs: Enabling Fast, Scalable Deployment

- Innovation and Quality Assurance in China’s Padel Court Factories

- FAQ Section