Understanding the Impact of Padel Turf Factories on Court Performance

The Evolution of Artificial Turf for Padel Courts as the Professional Standard

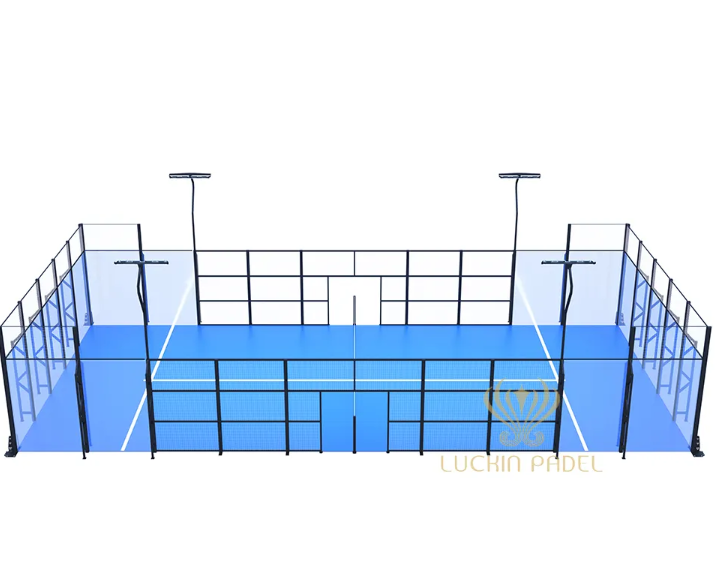

Padel turf production has really changed what we think about artificial surfaces for courts. Back in the day, most places just laid down regular synthetic grass, but nowadays pros require something much better suited for actual padel matches. The game itself creates different demands on the court surface compared to other sports, so manufacturers had to get creative. They've learned quite a bit about how certain textures affect where balls bounce, how players move around, and ultimately impacts everyone's enjoyment during play. Top companies these days make special padel turf featuring carefully crafted fibers, better filling materials between blades of grass, plus stronger backing layers. All these components come together pretty well to create courts that perform consistently whether it's sunny outside or raining cats and dogs.

How Padel Turf Factories Influence Surface Consistency and Player Safety

What happens inside those good padel turf factories really matters when it comes to keeping surfaces consistent and players safe. When manufacturers maintain tight control over their production areas and stick to rigorous quality checks, they end up with turf that has evenly spread fibers, pretty much the same pile height throughout, and decent shock absorption from one batch to the next. All this attention to detail means balls bounce predictably on court, which is great news for players trying to avoid injuries. The right balance between grip and sliding helps too. Well made turf takes pressure off joints but still holds firm enough during those quick direction changes everyone sees in professional matches. After all, padel involves so many sudden stops and starts that even small improvements in surface engineering can make a big difference in player performance and long term health.

Key Features of High-Performance Padel-Specific Artificial Turf

What sets premium padel turf apart from regular artificial grass are those special technical features most people never think about. The fibers made from UV stabilized polyethylene stand around 10 to 15 millimeters tall, which means they last longer and give balls a predictable bounce every time. Behind the scenes, advanced backing systems keep everything stable so the turf doesn't warp or shift over time. And water drains away quickly too. For the underfoot experience, manufacturers mix silica sand with rubber granules in just the right proportions. This combination absorbs impact without making the surface too soft. Top quality surfaces from established factories really do hold up year after year, even when courts get packed with matches and weather takes its toll. Players notice the difference after a few games on these surfaces compared to cheaper alternatives.

Evaluating Fiber Technology and Durability in Padel Turf Manufacturing

Polyethylene monofilament vs. fibrillated fibers: Performance differences

Padel courts built for high performance typically use either polyethylene monofilament or fibrillated fibers as their main components. Monofilament stands out for lasting much longer than fibrillated options, sometimes sticking around about 40% longer based on what industry experts have seen. Courts made with these fibers tend to give players consistent ball bounce and stable footing, which is why pros often prefer them for serious matches. Fibrillated fibers can help keep the infill material in place better and might make the game feel faster, but they don't hold up as well when exposed to regular wear and tear. When deciding between these materials, factors like how intense the usage will be, local weather conditions, and how much maintenance someone wants to do all come into play.

Tensile strength and fiber resilience in high-impact padel play

The best quality padel turf is made from polyethylene fibers that have tensile strength around 12 to 15 cN/dtex. These materials are designed to handle all those quick side to side moves and constant sliding that happens so much in today's game. What makes these fibers special is their memory effect, which basically means they bounce back up after getting hit, so they don't flatten out over time and keep giving players the same feel every time they strike the ball. Manufacturers also use some pretty smart anchoring methods when making this turf, which stops the fibers from coming loose too soon, even when courts get heavy use day after day.

How dtex and pile height affect ball bounce and foot traction

The fiber thickness measured as dtex along with pile height play a big role in how games actually play out on artificial surfaces. Most top quality turf installations sit around 13 to 15 millimeters for pile height, with stitching packed at over 18 thousand per square meter. This setup generally gives balls a consistent bounce range between about 135 and 145 centimeters high. When manufacturers increase the dtex rating, they get better lasting power and firmer playing surfaces. Getting the pile height just right creates enough friction so players can move safely without slipping too much or getting stuck. These factors work together to find that sweet spot where athletes have good traction but still maintain control during intense competition situations.

Abrasion resistance and UV stability for long-term durability

The best quality padel turf stands up to wear and tear thanks to some pretty smart material science. These surfaces can handle well over 300 thousand abrasion tests before they start looking worn out. Special UV treatments keep the colors looking fresh and stop the fibers from breaking down when exposed to sunlight for long periods. The backing system has multiple layers made from a mix of latex and polyurethane, which helps hold onto those fibers around 40 percent better than cheaper single layer options. For businesses installing this stuff commercially, most manufacturers guarantee at least eight years of good performance, even when weather throws challenges their way. That kind of durability makes all the difference in maintaining consistent play conditions year after year.

Core Components: Infill Systems, Backing Technology, and Modular Design

Role of infill systems and backing technology in performance and longevity

What makes a great padel court really stand out comes down to three main parts working together: the infill material, the backing system, and how the surface is designed. Most courts use a mix of silica sand combined with those rubber granules made from SBR. This combination helps absorb impact when players run and jump, cuts down on tired legs after long matches, and keeps balls bouncing consistently across the court. For the backing layer, manufacturers often go with either multiple layers of polypropylene or special polyurethane coatings. These materials keep the court dimensions stable even under heavy use, allow water to drain away at impressive speeds (around 60 liters per minute per square meter), and stop fibers from coming loose over time. When all these components are properly maintained, they not only affect how well the game plays but also how long the court lasts before needing replacement, sometimes stretching beyond eight years if cared for correctly.

Silica sand and rubber granule ratios for optimal shock absorption

What goes into the infill mix really matters when it comes to both player safety and how well the court performs. Most top courts stick with around 70% silica sand mixed with about 30% rubber granules. The sand gives the surface its solid base and keeps things stable, whereas the rubber adds that nice bounce back effect and helps soak up shocks from jumps and falls, cutting down impact forces by roughly 55 to 65 percent according to World Padel Tour specs. Getting this right means players' knees stay protected without making the ball behave unpredictably. When manufacturers get the mix wrong though, we start seeing problems like erratic bounces or higher chances of getting hurt during play. That's why many production facilities tweak their formulas depending on where they're located. In places with harsh winters, they tend to throw in extra rubber so the surface stays pliable even when temperatures drop.

Modular turf systems for easy installation and maintenance

Court builders are seeing big changes thanks to modular turf systems made from those handy pre-fabricated interlocking panels. These panels let folks install courts much faster than before and make fixing problems a lot easier too. When something gets damaged on regular rolled turf, they usually have to replace huge sections at once. But with modular setups, only the broken parts need replacing which means courts stay open longer and save money over time. The way these modules fit together creates really consistent seams across the whole surface. This matters because balls bounce predictably and players don't trip over uneven spots. A recent study from last year showed pretty impressive results too. Sports facilities that switched to modular turf saw about 40 percent less spending on upkeep compared to old school methods. Makes sense when thinking about all those saved repair hours and fewer disruptions during games.

Certifications, Testing, and Quality Assurance in Padel Turf Factories

Essential certifications: ISO 9001, EN 15330-1, and third-party testing

When looking at manufacturing quality, certifications really matter. ISO 9001 basically tells customers that a company maintains consistent quality control across all stages of production. Then there's EN 15330-1 which specifically checks if sports surfaces meet important safety requirements like how much they absorb impact, deform when pressure is applied, and how balls bounce off them. Independent lab tests go even further by checking things like how materials hold up under sunlight, resist wear and tear, and perform safely in actual use conditions. All these different certifications together create what many in the industry consider the gold standard for quality assurance. Manufacturers who display these credentials on their websites or product packaging tend to stand out from those without any formal recognition at all.

Supplier evaluation criteria: Transparency, test results, and warranties

When looking at suppliers, don't stop at certifications alone. Check how transparent they are about their materials and performance data. Good quality manufacturers will share actual test results from different production runs showing how well their products handle wear and tear over time, including things like resistance to abrasion, breakdown from sunlight exposure, and ability to bounce back after compression. Most serious companies offer solid guarantees that last around 8 years or longer specifically for issues related to sun damage and weak seams. Top tier producers also get checked regularly against ISO 9001 standards, especially when it comes to proper welding techniques and protection against rust. About three quarters of big sporting events now insist on meeting EN 14620 requirements before approving any synthetic turf surfaces for competition use.

The role of manufacturers in delivering reliable, quality-assured turf systems

Good quality manufacturers make sure they check everything from when they pick out the raw materials all the way until the last product gets inspected. They have tracking systems in place so they can follow each component as it moves through mass production lines, which stops bad products from getting mixed in with good ones. The companies run checks right there on the production floor too, catching problems before they become bigger headaches later on after installation. Most serious manufacturers will actually provide pretty thorough instructions for how to install their products properly and what kind of regular maintenance needs doing over time. This attention to detail really matters because when padel turf factories stick to global quality standards and do proper testing throughout manufacturing, they end up creating playing surfaces that not only satisfy professional requirements but also keep players safe during matches and ultimately save money over the life of the court surface.

Customization and Turnkey Solutions from Leading Padel Turf Factories

Tailored Technical Specifications and Design Customization Options

Top manufacturing plants provide all sorts of customization options to fit what each project actually needs. They can work with different fiber mixtures, adjust pile height anywhere from 12 to 20 millimeters, and even create backing systems that perform better in specific climates. The production process is pretty advanced when it comes to getting colors just right, adding logos where needed, and creating drainage systems that match the requirements. Most companies use computer aided design software along with detailed material databases to plan out court spaces efficiently. This helps maximize available area while ensuring players move around comfortably and the surface performs at its best during games.

End-to-End Turnkey Services: From Manufacturing to Installation Support

Top padel turf manufacturers offer everything needed for a complete project, handling everything from production right through to delivery and actual installation on site. Their service package usually starts with assessing the specific location requirements, then moves onto advising about proper base preparation before sending their experts to oversee the work firsthand. They also train staff after installation so everyone knows how best to maintain the surface. The whole process maintains strict quality standards at every stage, beginning with checking material specifications all the way until the system is officially handed over. Skilled crews can generally finish most installations in around four days give or take, which cuts down waiting periods dramatically when compared to dealing with multiple separate suppliers who might not coordinate as well.

Case Study: Full-Service Factory Support in a European Padel Academy Project

A well known sports academy in southern Europe recently teamed up with one of the best padel turf makers to build their new complex featuring eight courts. The manufacturer wasn't just selling products but actually helped with the whole design process from start to finish. They created special turf that stands up better against sun damage and provides better cushioning for players' joints. Their own trained crews came in to install everything properly. What makes this setup work so well is how they adapted materials based on local weather conditions and what happens during heavy training sessions. Using this all-in-one approach cut down construction time by around forty percent compared to when different companies handle each part separately. Academy staff have been really impressed with how consistent the playing surface stays throughout the day and how much less upkeep is needed overall.

Frequently Asked Questions

What is the optimal pile height for padel turf?

The optimal pile height for padel turf is usually between 10 to 15 millimeters, ensuring durability and consistent ball bounce.

How long does padel turf typically last?

Padel turf typically lasts around eight years with proper maintenance, even under heavy usage and challenging weather conditions.

What mix of materials is used in padel turf infill systems?

Most padel turf infill systems use a mix of 70% silica sand and 30% rubber granules for optimal shock absorption and performance.

What are modular turf systems?

Modular turf systems consist of interlocking panels that allow for quicker installation and easier maintenance compared to traditional rolled turf.

What certifications should I look for in padel turf factories?

Look for certifications such as ISO 9001 for quality control and EN 15330-1 for safety standards in padel turf factories.

Table of Contents

- Understanding the Impact of Padel Turf Factories on Court Performance

- Evaluating Fiber Technology and Durability in Padel Turf Manufacturing

- Core Components: Infill Systems, Backing Technology, and Modular Design

- Certifications, Testing, and Quality Assurance in Padel Turf Factories

- Customization and Turnkey Solutions from Leading Padel Turf Factories

- Frequently Asked Questions