The Global Rise of Padel and China’s Strategic Role in Court Supply

Phenomenon: Surging Global Demand for Padel Infrastructure

The padel court market around the world is booming right now because more people are getting into the sport and cities are building new sports facilities. Europe and North America still have big markets, but Asia Pacific is where things are really taking off fast. Countries such as China, India, and Japan are putting money into building special courts inside city spaces and fancy residential areas. Why? Well, folks have more spare cash these days, there's been a real uptick in popularity for easy-to-play racquet games, and governments want citizens to be more active. With all this demand for good quality courts, places that can make them in large quantities matter a lot for the worldwide business. China especially stands out as a major player in producing these courts at scale.

Principle: China’s Competitive Edge in Sports Facility Manufacturing

The manufacturing capabilities in China provide a major edge when it comes to making padel court systems. The country has well established supply chains for materials such as steel and tempered glass, plus access to modern fabrication tech and workers who know their stuff. These factors combine to create substantial cost savings through large scale production. As a result, manufacturers can offer full padel court packages including everything from metal frames and safety glass panels right down to tensioned nets and all necessary fittings at prices far below what's typical in European or North American markets. When companies cut out middlemen by selling directly from factories, the price drops even further while still maintaining quality standards needed for serious competitive play.

Trend: Growing Export Volume of Padel Court China Units (2020–2024)

Chinese exports of full padel court systems have been climbing since 2020 right through to 2024. This growth shows what people want around the world plus it proves that Chinese makers can now produce courts that meet international standards. We see this happening most in Europe where businesses run clubs and resorts, but also across developing countries looking to build out their sports infrastructure without breaking the bank. A lot of these buyers skip the middlemen altogether and go straight to certified factories in China. They're after good value without sacrificing quality or speed of delivery, especially when they need to install multiple courts at once for big developments.

Engineering Durability: Materials and Construction of Padel Court China Systems

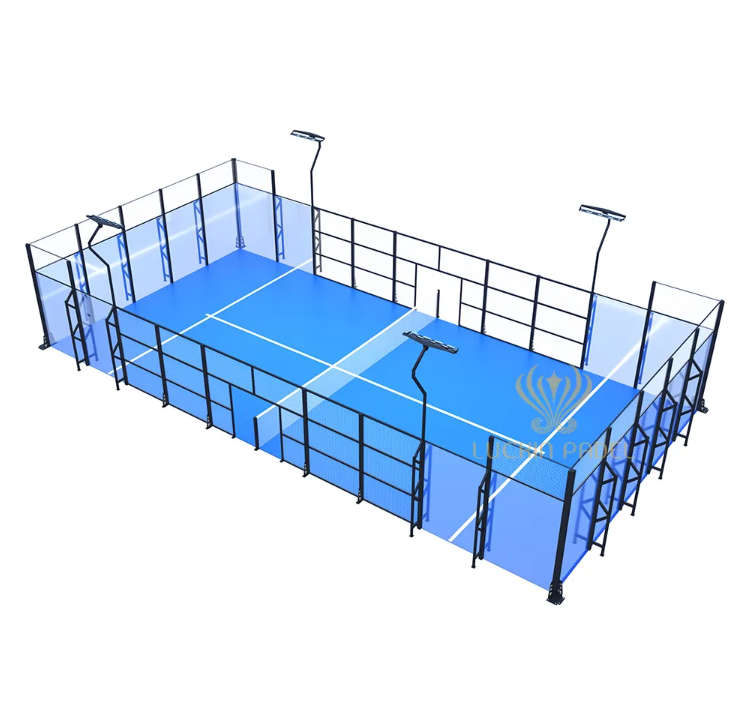

Core Components: Steel Frames, Tempered Glass, and High-Tension Mesh

What makes a Chinese made padel court last so long? Let's start with the basics. Most courts have galvanized steel frames as their backbone, along with tempered safety glass and tight woven mesh systems. When it comes to steel quality, manufacturers usually go for either Q235 or Q345 grades according to GB/T 700-2006 standards. These steels need to handle at least 235 MPa before bending and can stretch up to around 500 MPa when pulled hard. For the glass panels, they get heat treated until they reach compression forces over 95 MPa on the surface. This treatment makes them much harder to break during play. The mesh itself is pretty impressive too. Stainless steel wires about 2 to 2.5 mm thick form a grid pattern with holes roughly 44 by 44 mm apart. This setup allows balls to bounce back properly while keeping everything stable even when subjected to forces as high as 1200 Newtons of tension.

Glass and Frame Durability: Meeting Outdoor Performance Standards

Chinese padel courts built to last outdoors use special coatings and treatments on their materials. The steel frames get a zinc coating around 80 to 100 microns thick, which protects against rust for about 15 to 20 years even in places with normal weather conditions. For the glass panels, manufacturers combine both heat treatment and chemical strengthening methods. When broken, this glass shatters into roughly 40 to 80 small pieces within each 25 by 25 centimeter area, meeting and actually going beyond the EN 12600 safety standards set in Europe. Lab tests simulating harsh weather conditions reveal that these materials keep about 95% of their strength after being exposed to UV light for 10,000 hours and subjected to extreme temperatures ranging from minus 30 degrees Celsius all the way up to 60 degrees. This makes them work well no matter where they're installed around the world.

Data Insight: Lifespan Comparison – Chinese vs. European-Built Padel Courts

Studies show that properly installed and maintained Chinese made padel courts typically last around 12 to 15 years, whereas top European models tend to stick around for about 15 to 18 years. The latest numbers from the International Sports Facility Report in 2024 point to something interesting happening since 2020. What used to be a big difference in durability (about 35%) has shrunk down to roughly between 15 and 20%. Still, Chinese systems generally come with a price tag that's 40 to 50% lower than their European counterparts. How long these courts actually last really comes down to how good the base work was, whether everything got put together right, and how regular the upkeep is. So when someone talks about where the court came from, it's not the only factor that determines how many years it will serve.

Cost Efficiency and Value: Why Padel Court China Options Dominate the Market

Cost Breakdown: Building a Padel Court – China vs. Local Procurement

Getting a padel court made in China usually saves between 40 and 60 percent compared to buying one locally in Western countries. For example, a complete European manufactured court will set someone back around $35k to $55k, while similar setups coming out of China start at just $15k and go up to about $25k. The reason for this big difference? Manufacturers there have everything under control from materials to assembly, plus cheaper labor rates and massive production volumes. These cost advantages mean top quality courts are now within reach for sports clubs, city planners, and property developers across the globe. As a result, we're seeing padel spread faster than ever before as more communities can afford to build proper facilities without breaking the bank.

Factory Direct Model: Eliminating Distributor Markups

Many Chinese factories work directly with clients instead of going through middlemen who just drive up costs. When companies cut out these extra layers, they get clearer pricing structures, can customize products better, and talk straight to the people actually making their goods. For businesses looking to place orders, this means they have much more control over exactly what gets produced and can make changes quickly if needed. Plus, there's no need to pay for all those extra fees and markups that come with traditional supply chains involving multiple distributors and wholesalers across different regions.

Balancing Affordability and Risk: Addressing Quality Concerns in Low-Cost Units

Affordability definitely has its appeal, but doing proper research before buying makes all the difference in getting real value over time. Good manufacturers address quality worries by offering things like ISO 9001 and CE certifications, along with thorough material test results, solid warranty coverage, and actual help with installation when needed. The old idea that something cheap must be bad quality just doesn't hold water anymore. Many top Chinese manufacturers have stepped up their game significantly. They've implemented sophisticated quality checks similar to what we see in Europe, yet still manage to keep prices competitive because they run operations efficiently without cutting corners. This approach allows them to maintain both quality standards and price advantages simultaneously.

Quality Assurance: Certifications and Standards in Padel Court China Production

Looking for a padel court system from China? International certifications are pretty much essential when evaluating whether something meets basic standards or not. Top manufacturers typically have ISO 9001 certification covering their quality control processes, plus the CE mark which shows they meet European safety requirements. Many also carry SGCC certification specifically for the tempered glass components used in courts. Why does this matter? Well, these certifications basically guarantee that the product will perform structurally sound over time, last through regular use, and most importantly keep players safe during matches. Whether installing at a club level facility or building a private court, proper certification isn't just paperwork it's actual proof that the manufacturer stands behind their products.

ISO, CE, and SGCC Certifications: Validating International Compliance

Getting certified sets up some basic trust markers, though nobody can really know if something is genuine until they check it out themselves. When looking at products with the CE mark, there needs to be proper paperwork backing it up including that official Declaration of Conformity plus all the technical specs behind it. The ISO 9001 standard basically keeps things running smoothly throughout production processes. We're talking about everything starting with picking out materials right through to putting together the finished product. For anyone working on meaningful projects, these certification requirements aren't just suggestions either. They actually affect whether regulators will approve the work, what kind of insurance protection might be available, and how well whatever gets built will hold up over time in real world conditions.

Transparency Challenge: Identifying Reputable Manufacturers vs. Distributors

A lot of players in this space are actually resellers or trading firms who don't have their fingers on the pulse of actual production processes. Legitimate manufacturers will typically provide transparency documents like factory audits, material testing results, and can show real world projects they've completed. Smart buyers want to see tangible evidence when assessing manufacturing capabilities. Facility visits or even video footage of operations go a long way toward separating genuine OEMs from those acting as intermediaries. Taking these extra steps helps avoid headaches down the road with inconsistent product quality issues and the inevitable support problems that come after purchase.

The Quality Paradox: Certified Factories with Inconsistent On-Site Execution

Certified factories aren't immune to problems when installations happen on site, often because field crews just don't match what happens back at the factory floor. We've seen plenty of cases where bad groundwork, lousy drainage systems, or rushed assembly really hurt how things perform down the road. The best approach? Get those comprehensive installation guides ready, bring in someone who knows what they're doing for setup, and definitely check everything before shipping out. According to industry reports, construction sites that have proper oversight end up with about 40% fewer headaches after everything's installed, which means the finished product actually works like it was supposed to according to the blueprints.

Selecting a Trusted Padel Court China Supplier: A Professional Framework

Step-by-Step Evaluation of Reliable Chinese Padel Court Manufacturers

It makes sense to start by figuring out if we're dealing with a direct manufacturer or going through a distributor since this really impacts what we pay, how long delivery takes, and how much we can customize things. Most often, working directly with manufacturers tends to cut costs somewhere around 20 to maybe even 30 percent while giving better control over product specs. We should look at their business registration documents, check for ISO certification marks, and see what kind of building qualifications they actually have. Then it's good practice to compare those credentials against actual projects they've completed before, especially ones done in similar settings like public facilities, recreational centers, or businesses. Some studies show companies that have been around for more than a decade tend to face about 37 percent fewer problems with structures after five years of operation. That kind of data really underscores why having a solid history matters when choosing suppliers.

Key Selection Criteria: Experience, Portfolio, and After-Sales Support

When looking at potential suppliers, check how well they handle different aspects like civil construction projects, metal framework installations, glass system implementations, and turf field integrations. Take a good look through their project history to see if they've worked on varied sized jobs with different levels of difficulty. Don't forget to ask for references from clients who operate in similar environments where weather conditions and usage patterns match what we expect here. What happens after the sale matters too. Good suppliers will provide straightforward warranty details, proper technical manuals, and actually respond when problems arise during operation. The contract itself needs to spell out exactly what materials will be used, when things need to arrive on site, and what kind of help is available during installation. Clear definitions prevent misunderstandings down the road.

One-Stop Solutions: From Design and Manufacturing to Installation Support

When looking for suppliers, go with those who can handle everything from start to finish – design help, actual manufacturing, getting stuff delivered, even guidance on how to install it all properly. This kind of all-in-one package really helps keep things consistent across projects while cutting down on all the back and forth needed between different companies. The best partners will actually send over detailed blueprints, tell clients exactly how to prepare sites beforehand, and stick around to offer hands-on help during setup. Before finalizing anything, make sure they can tweak sizes or add company logos without breaking any of the official padel rules from places like Europe or South America. Working with vendors who offer this full range of services makes the whole project run smoother and tends to create systems that last longer without constant maintenance headaches down the road.

Frequently Asked Questions (FAQ)

Why is there a surge in demand for padel infrastructure globally?

The demand for padel infrastructure is rising due to the sport's growing popularity, especially in regions like Europe, North America, and Asia Pacific. It is considered easy to play and is encouraged by governments aiming to promote an active lifestyle among citizens.

What makes China a significant player in padel court manufacturing?

China's well-established supply chains for materials, access to modern fabrication technology, and a skilled workforce enable the country to produce padel court systems cost-effectively at scale, leading to global market leadership.

How does the cost of Chinese-made padel courts compare to European-made ones?

Chinese-made padel courts are generally 40% to 50% cheaper compared to European-made versions, offering substantial savings due to efficiencies in materials procurement, labor, and large-scale production.

What certifications are important when selecting a padel court from China?

Relevant certifications include ISO 9001 for quality management, the CE mark for European safety standards compliance, and SGCC for tempered glass components, ensuring structural performance and player safety.

How can buyers distinguish between genuine manufacturers and resellers?

Buyers should seek transparency documents like factory audits, view real-world projects completed, and possibly visit facilities or view operation videos to verify production capabilities and ensure they are dealing directly with manufacturers.

Table of Contents

- The Global Rise of Padel and China’s Strategic Role in Court Supply

- Engineering Durability: Materials and Construction of Padel Court China Systems

- Cost Efficiency and Value: Why Padel Court China Options Dominate the Market

- Quality Assurance: Certifications and Standards in Padel Court China Production

- Selecting a Trusted Padel Court China Supplier: A Professional Framework

-

Frequently Asked Questions (FAQ)

- Why is there a surge in demand for padel infrastructure globally?

- What makes China a significant player in padel court manufacturing?

- How does the cost of Chinese-made padel courts compare to European-made ones?

- What certifications are important when selecting a padel court from China?

- How can buyers distinguish between genuine manufacturers and resellers?