Understanding the Major Cost Drivers in Padel Court Construction

Key cost components of padel court construction

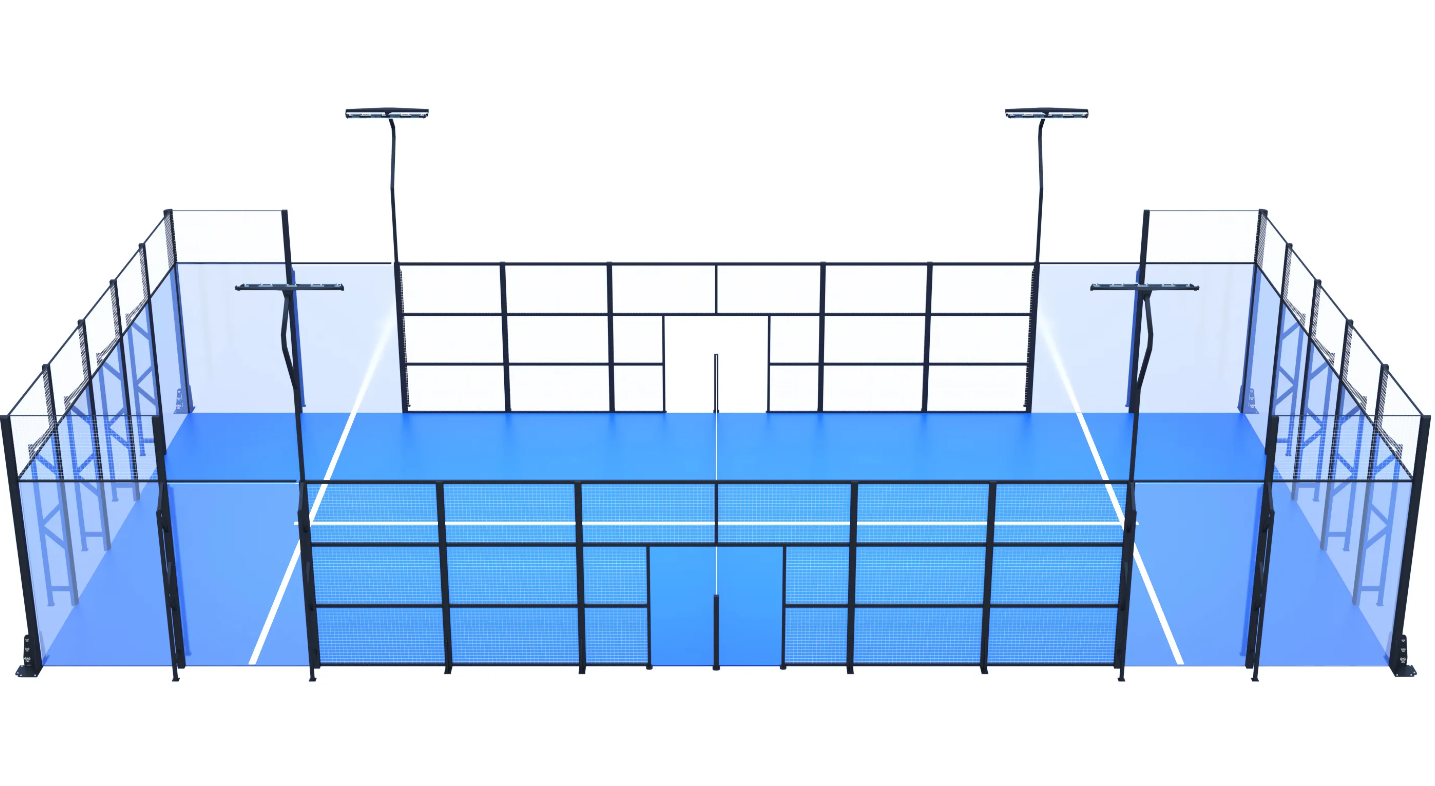

When it comes to building padel courts, most of the money goes towards four main areas. The surface material takes up around 30 to 35 percent of the total budget, followed by enclosure systems at about 25 to 30 percent. Foundation work accounts for roughly 20 to 25 percent, and then there's lighting plus those extra features which make up the remaining 10 to 15 percent. For artificial turf surfaces, expect to pay somewhere between eight and twelve dollars per square foot. Tempered glass walls are necessary if the court needs to meet professional standards, but they come with a price tag that's about 40 percent higher than what polycarbonate options would cost. Foundations made with structural steel and poured concrete usually fall in the range of fifteen to twenty eight dollars per square foot, though this can vary quite a bit based on what kind of soil we're dealing with at the site.

Regional cost variations in construction across the U.S. and UK

Labor and material disparities create significant price gaps:

| Region | Average Cost Range | Primary Cost Factors |

|---|---|---|

| UK | £25,000–£40,000 | Planning permissions, skilled labor shortages |

| U.S. | $50,000–$100,000 | Imported materials (55%), ADA compliance requirements |

Urban projects in London and New York face 18–22% higher costs due to logistical challenges and stricter building codes compared to rural installations.

Indoor vs. outdoor court costs: What drives the difference?

Setting up indoor facilities costs roughly 60 to 75 percent more at the start because of all the climate control systems needed, which alone run around $12 to $18 per square foot. Then there are those fancy drainage systems too expensive compared to what's used outdoors – about $4.50 versus just $2.80 per square foot. And let's not forget about reinforcing the roof structures, something that adds another 40% onto material expenses. Outdoor courts might seem like the budget option when first building them out, but they actually end up costing about 30% more over time for repairs from sun damage and general weather wear on surfaces and equipment alike.

Data insight: Average cost range of padel court construction in the UK and U.S.

The baseline construction cost for a single professional-grade court averages £32,500 in the UK (2024 market data) versus $68,000 in the U.S., excluding land acquisition fees. Premium installations with player amenities such as spectator seating and VIP areas can double these figures in both markets.

Optimizing Site Preparation and Base Construction for Cost Efficiency

Effective site preparation forms the bedrock of cost-efficient padel court construction, influencing 18–22% of total project expenses according to 2023 sports facility analyses. Strategic planning during this phase prevents costly redesigns and ensures regulatory compliance throughout the build.

Ground Preparation and Site Work: Minimizing Hidden Costs

Thorough soil analysis before excavation identifies unstable substrates, preventing expensive foundation repairs later. A 2024 geotechnical study found proper land clearing and grading reduced earthworks costs by 15% in urban padel projects. Removing vegetation and leveling terrain in a single operation minimizes machinery rental fees and accelerates timelines.

Sub-Base & Base Construction: Material and Labor Efficiency

When laying down crushed stone aggregates from local sources, aim for a layer thickness around 4 to 6 inches thick. Compaction should happen in stages until reaching about 95% density, which is what most folks in the business consider standard for supporting heavy loads. Getting this right matters a lot for road stability. The newer laser guided grading tools make all the difference here. They really boost the accuracy of those base layers, cutting down on wasted materials by roughly 20% when compared to old fashioned hand methods. That saves money in the long run. For places where it rains a lot, putting geotextile fabric between the soil underneath and the stone layer helps stop erosion problems before they start. Contractors who skip this step often end up spending extra cash fixing damage later on down the road.

Drainage Installation for All-Weather Play Without Overspending

Drainage systems that incorporate slopes between 1 and 2 percent along with perforated PVC piping can cut installation expenses down by around 30 percent when compared to systems installed after the fact. When dealing with those stubborn clay soils, there's this thing called hybrid drainage mats that handle both filtering and spreading out water across the area at roughly four to six dollars per square meter. That works out to be about forty percent less expensive than going with old school gravel based systems which nobody really likes anymore. And if we're talking about areas with moderate weather conditions, permeable resin surfaces actually make a big difference too, cutting back on how much drainage work needs to be done overall. Just ask anyone who has dealt with these issues firsthand.

Choosing Cost-Effective Materials Without Sacrificing Quality

Comparing Padel Court Surface Materials: Artificial Grass vs. Resin Coatings

Around 18 to 22 percent of what it costs to build a sports facility goes into the actual playing surface, so picking the right materials really matters. Artificial turf typically ranges from about £32 to £48 per square meter. It absorbs shocks better and needs less upkeep compared to resin surfaces which cost between £40 and £55 per square meter. But there's a trade off here because resin gives players more consistent ball bounce. According to a recent industry report from last year, resin coated courts actually needed about 35% fewer fixes during their first five years of operation. That means while they might cost more upfront, they tend to save money in the long run when considering all those repair bills down the road.

Enclosure & Rebound Walls: Glass, Mesh, and Hybrid Options for Cost Control

Full-glass walls (£12,000–£18,000 per court) deliver professional-grade performance but increase budgets by 25% compared to mesh-glass hybrids (£8,500–£11,000). Polycarbonate-mesh combinations reduce initial costs by 40% while maintaining 85% of glass’s optical clarity, according to leading suppliers.

Design Options Affecting Construction Cost: Stepped vs. Uniform Walls

Stepped wall designs add £1,200–£1,800 in labor due to complex installations but improve airflow for outdoor courts. Uniform 4m walls streamline prefab assembly, cutting build time by 12–15 hours per court without compromising functionality.

Premium Finishes vs. Functional Durability: Balancing Aesthetics and Budget

Anodized aluminum finishes add £3,500–£4,200 per court for enhanced weather resistance, while powder-coated steel provides comparable protection at 60% lower cost. Textured resin coatings replicate premium aesthetics without the 30% price premium of custom designs.

Using Modular and Prefabricated Designs to Reduce Build Time and Labor Costs

Modular and prefabricated court designs: Faster build, lower labor cost

Building with modular components can cut costs because around two thirds to four fifths of everything gets made at factories while the site is still being prepped. According to people who work with prefabs all day long, projects tend to wrap up anywhere from 30% to half again as fast as regular construction does. Take the new sports facility going up in Birmingham right now for instance they saved nearly 18% on their budget just by using standard sized modules throughout the design. When things are built indoors instead of outside, bad weather doesn't hold everything up anymore. Plus those fancy glass walls line up perfectly every time and basketball courts get laid out straight without any wobbling edges.

Case Study: Cost savings from prefab installation in urban UK locations

A London leisure center cut its £120,000 construction budget by 22% using prefabricated steel-reinforced walls and pre-assembled drainage systems. The modular design avoided £15,000 in crane rental fees by enabling manual installation in tight urban spaces.

Trend: Rising adoption of off-site construction in padel infrastructure

Over 65% of UK padel operators now request modular designs, up from 32% in 2020. This shift reflects growing recognition of prefabrication’s dual advantage: 25% faster ROI through accelerated timelines and 15–20% lower long-term maintenance costs compared to site-built courts.

Minimizing Ancillary and Long-Term Operational Costs

Essential ancillary equipment: Lighting, netting, and maintenance tools

While court construction represents 60–70% of initial expenses, ancillary items like LED lighting, anti-wear nets, and surface groomers account for 15–20% of lifetime costs. Perimeter mesh with UV stabilizers lasts 3–5 years—nearly double the lifespan of standard alternatives—reducing replacement frequency and labor.

Energy-efficient lighting solutions for long-term savings

Modern LED systems consume 55–60% less energy than traditional metal halide fixtures while improving court illumination. According to the 2023 Sports Facility Lighting Report, clubs using smart lighting controls with motion sensors reduced monthly energy bills by £180–£240 ($230–$300) per court through optimized usage patterns.

Navigating planning permission and regulations to avoid delays and fines

Thirty percent of UK padel projects face 4–6 week delays due to non-compliance with zoning laws, adding £2,500–£4,000 ($3,100–$5,000) in unexpected costs. Outdoor courts often require noise impact assessments, while indoor installations must meet ventilation standards of 12 air changes per hour.

Strategy: Early consultation with local authorities to reduce compliance costs

As highlighted in the 2024 Construction Cost Management Study, pre-application meetings with planning departments cut approval delays by 30% on average. Many municipalities offer expedited reviews for projects incorporating renewable energy or sustainable drainage solutions, helping developers save time and reduce risk.

FAQ

What is the most cost-effective surface material for a padel court?

Artificial turf is generally more cost-effective upfront, but resin coatings offer long-term savings by requiring fewer repairs over time.

How do prefabricated designs save on padel court construction costs?

Prefabricated designs save on costs by reducing build time and labor expenses, with up to 18% savings reported in some projects.

Why are indoor padel courts more expensive to construct?

Indoor courts have higher initial costs due to climate control systems and the need for reinforced roofing, compared to outdoor courts.

How can I ensure my padel court construction project stays on budget?

Investing in thorough site preparation, choosing cost-effective materials, and consulting early with local authorities can help keep construction costs under control.

Table of Contents

- Understanding the Major Cost Drivers in Padel Court Construction

- Optimizing Site Preparation and Base Construction for Cost Efficiency

- Choosing Cost-Effective Materials Without Sacrificing Quality

- Using Modular and Prefabricated Designs to Reduce Build Time and Labor Costs

- Minimizing Ancillary and Long-Term Operational Costs

- FAQ