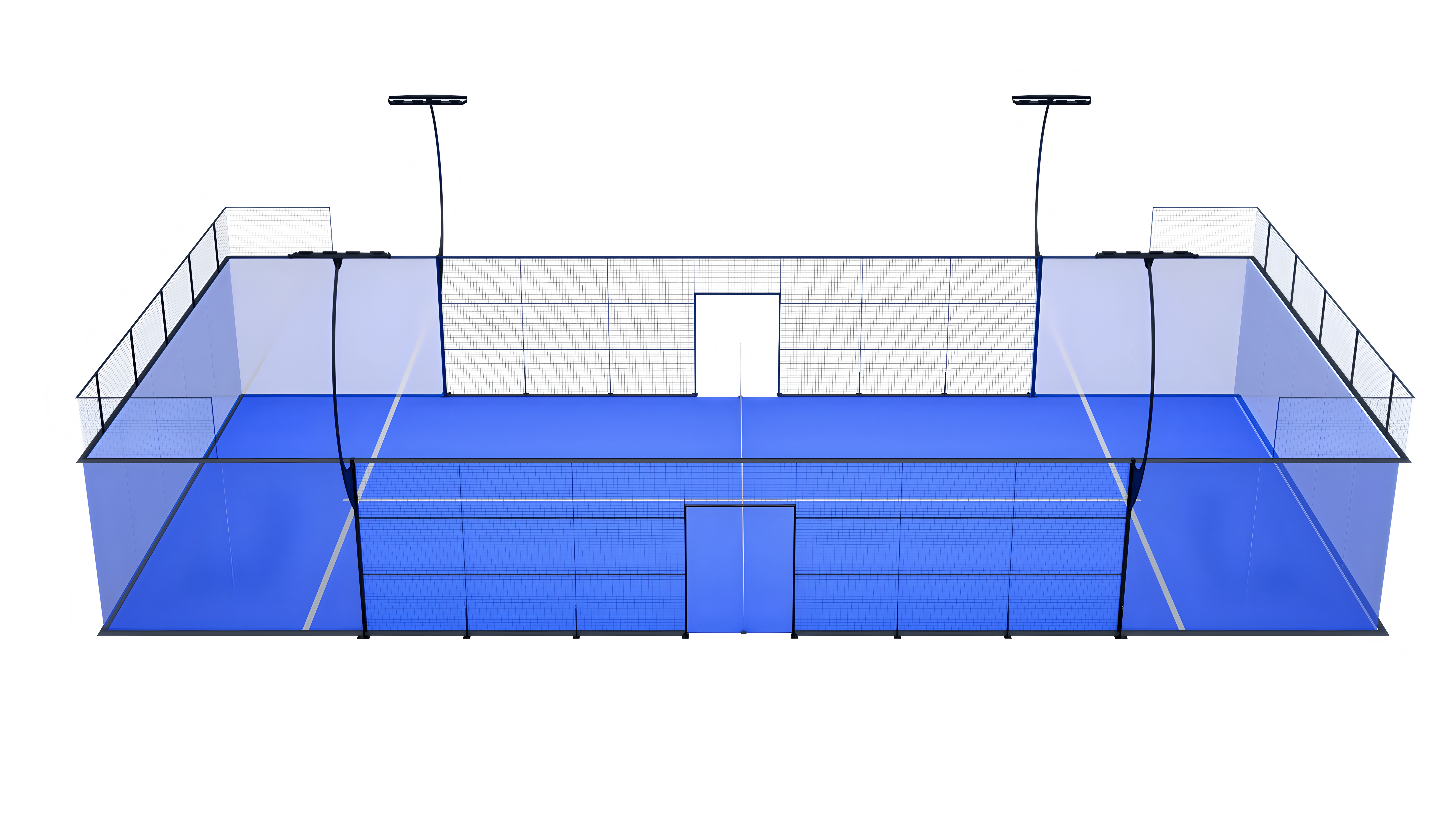

Superior Performance and Playing Experience from Premium Padel Turf

How Top-Tier Padel Turf Factories Engineer Optimal Ball Bounce and Player Safety

Top manufacturers of padel turf manage to hit those FIP standards for ball bounce at around 80% or better through a mix of special polyethylene fibers and silica sand as infill material. Courts typically feature grass blades between 12 to 16 millimeters tall, combined with roughly 2,000 to 3,500 kilograms of infill spread across each playing area. This setup results in surfaces where balls behave predictably most of the time, which makes a big difference when playing. Ankle strain drops by about 18% on these surfaces compared to what happens on regular concrete courts according to research from the Spanish Sports Council back in 2023. Beneath all that lies shock absorbing backing materials that return over 20% of impact energy, giving extra protection especially when players need to move sideways quickly during intense matches.

Consistent Playability Across Climate and Usage: The Role of Advanced Fiber Technology

Monofilament fibers treated with UV stabilizers show only about 3% variation in performance across temperatures ranging from minus ten degrees Celsius all the way up to fifty degrees Celsius. That's a big improvement over regular fibrillated turf which tends to degrade at around 11%. The special cross-weave pattern helps keep those fibers standing tall rather than getting flattened down. After roughly five thousand hours of actual gameplay, these surfaces still retain about ninety two percent of their original grip characteristics, which matters a lot for areas where people constantly walk back and forth near glass walls. For installations in colder parts of Europe, manufacturers have developed frost resistant polymer mixtures that stop ice patches from forming on surfaces. These same materials also hold up well against heat in warmer regions like the Mediterranean without losing their effectiveness.

Case Study: Spanish Padel Federation-Approved Surfaces and FIP-Compliant Court Performance

A Valencia-based padel turf factory reduced tournament surface complaints by 40% after implementing textured fiber technology meeting FIP Standard 2023-07. Their certified surfaces demonstrate:

| Metric | Federation Requirement | Factory Result |

|---|---|---|

| Vertical Ball Bounce | 83–143 cm | 112 cm avg |

| Rotational Resistance | 30–50 Nm | 42 Nm |

| Shock Absorption | ≥20% | 24% |

The factory’s climate-adaptive production protocols now serve 78 FIP-licensed venues across three continents.

Durability and Long-Term Value of Padel Turf from Industry-Leading Factories

Extended Lifespan: 40% Longer Wear Resistance vs. Standard Synthetic Turf (FIP Report, 2023)

Top padel turf factories achieve superior durability through advanced polymer formulations and UV-stabilized fibers. A 2023 FIP study shows factory-engineered surfaces deliver 40% longer wear resistance than generic alternatives, retaining playability for 8–10 years with proper maintenance. This longevity stems from pre-tensioned installation systems and anti-compaction technologies that prevent fiber matting.

Performance in High-Traffic Zones: Reinforced Fibers and Backing Systems

Leading manufacturers reinforce service boxes and baseline areas with hybrid backing that combines latex stability with polyurethane flexibility. These zones utilize 20% denser tufting patterns (1,800 stitches/m² vs. industry-standard 1,500) to withstand intense lateral movements. The result is 35% less surface deformation after 5,000 play hours compared to conventional turf systems.

Monofilament vs. Fibrillated vs. Textured Turf: Comparing Longevity and Maintenance Needs

While monofilament turf offers premium ball response (80% consistent bounce rate over 5 years), textured varieties provide optimal player safety with 0.8-second rotational traction. Fibrillated surfaces strike a balance–requiring only biannual brushing versus quarterly maintenance for monofilament types. Top factories now offer hybrid designs merging monofilament durability with textured safety features, reducing replacement cycles by 18 months.

Innovation in Surface Technology and Infill Systems at Top Padel Turf Factories

Advanced Infill Solutions: EnviroFill and Smart Cooling Technologies for Thermal Regulation

Top manufacturers of padel turf are now using coated silica sand infills such as EnviroFill, and these can cut down on surface temps by around 15 degrees Fahrenheit when compared to older materials. What makes this stuff work so well? The formula includes those rounded quartz cores that don't pack together too tightly, plus special cooling agents that help move heat away from the surface. Many producers also incorporate Microban antimicrobial tech right into the mix itself. This helps keep things cleaner between games while still ensuring balls bounce predictably across the court. Another big plus is how the colors match up perfectly. Available options include blue, red, green, and black variants that look great together without leaving those ugly streaks we see on regular sand filled surfaces.

Enhancing Traction and Shock Absorption Without Compromising Player Safety

Top quality manufacturers have managed to boost rotational traction by around 40% using special hybrid fibers that mix the strength of monofilament with the textured surface of fibrillated materials. The bottom layer is designed to absorb shocks and is actually made from recycled rubber pieces, which cuts down on joint stress during play by approximately 22%. This still keeps within the safety standards set by FIP for players. Independent tests show that these playing surfaces stay pretty consistent too, with ball bounce variations staying under 2.5% even after thousands of hours of intense gameplay. That kind of performance consistency makes all the difference for serious athletes who need reliable footing week after week.

Case Study: USPA-Sponsored Factory Implementing Next-Gen Climate-Responsive Turf

A padel turf manufacturer certified by the USPA has started using phase change material tech in their desert installations lately. Even when outside temps hit 110 degrees Fahrenheit, they manage to keep the playing surfaces under 85 degrees most of the time. The turf itself is made with two layers - top layer has those UV resistant polyethylene fibers we all know about, and underneath there's something that wicks away moisture. This setup cut down on water usage by about half in places like the Middle East, which makes sense given how hot it gets there. What's interesting though is that despite all these changes, the court still meets FIP standards for play quality. Looking at feedback after installation, around 94 percent of athletes said they were happy with how predictable ball speeds remained regardless of weather conditions. Makes sense really, since nobody wants to deal with unpredictable bounces during matches.

Global Compliance and Certification Standards in Padel Turf Manufacturing

Meeting FIP, Spanish Padel Federation, USPA, and ISO Requirements for Official Courts

The best padel turf manufacturers really focus on meeting all sorts of international standards. They follow FIP rules about court size, how much the surface grips shoes, and whether balls bounce consistently across the court. Then there are the specs from the Spanish Padel Federation regarding how well the material holds up under sun exposure and different weather conditions. USPA has their own requirements too, mainly looking at how much impact gets absorbed when players jump or fall, with a limit of 2.5g vertical deformation max. Plus most top factories have those ISO 9001 and 14001 certifications which cover both product quality control and eco-friendly production methods. All these standards help make sure courts perform great during competitions while keeping athletes safer from injuries. Take the new FIP infill density guidelines from 2023 as just one example. Factories that apply them see around 18 percent improvement in grip measurements according to independent testing labs.

How Leading Padel Turf Factories Align Production with International Quality Benchmarks

Manufacturers who are certified use robotic systems for tension testing that check if fibers can withstand over 2,500 Newtons per meter of pull force. They also run spectral analysis to keep color consistency within plus or minus 5% between different production batches. For extreme conditions testing, they have climate chambers that simulate temperatures ranging from minus 20 degrees Celsius all the way up to 60 degrees. All this careful engineering means sports courts can stay compliant with FIP standards regarding bounce height measurements between 83 and 143 centimeters even after being used heavily for eight years or more. The latest research published in 2024 on material aging confirms these long term performance claims.

The Strategic Advantage of Partnering with Certified Manufacturers

When clients choose padel turf from standard factories, they typically get project approvals from sports authorities around 35% quicker. Plus, these surfaces qualify for FIP sanctioned competitions and rankings, something that matters a lot to serious players. There's also much less trouble with warranties too – about 90% fewer claims because the surfaces don't degrade as fast. Looking at the numbers from last year's market research, certified installations tend to sell for about 40% more when it comes time to resell. And installation companies report getting their work done 22% faster since inspectors spend less time checking compliance issues during site visits.

Cost-Efficiency, Sustainability, and Global Supply Chain Benefits

Reduced Lifetime Costs Through Low-Maintenance, Durable Artificial Grass

High quality padel turf made by top manufacturers actually saves money over time because it's built to last longer. Traditional court surfaces need constant resurfacing work, but these new materials with special polymer blends and UV protection fibers stay strong for around 8 to maybe even 12 years without much maintenance needed at all. The numbers back this up too - studies looking at how courts perform throughout their lifespan show that maintenance costs drop by roughly 60% each year when using this type of surface instead of regular synthetic grass, especially on those courts that meet FIP standards for professional play.

Water Savings and Eco-Friendly Infills: The Sustainable Edge of Premium Padel Turf

Modern padel turf factories eliminate water dependency while addressing environmental concerns. Eco-conscious infill systems using recycled rubber and organic materials reduce carbon footprints by 42% versus conventional alternatives (Supplier.io 2024). A 2023 study found these surfaces save 18 million liters of water annually per 50 courts–a critical advantage for drought-prone regions.

Reliable Global Distribution Networks Ensuring Fast, Scalable Installation

Strategic partnerships with logistics specialists enable top manufacturers to deploy materials to 90+ countries within 21 days. Centralized production hubs and regional warehouses mitigate supply chain disruptions, achieving 98% on-time delivery rates even during peak demand periods. This operational efficiency allows clubs to commission full-size courts 30% faster than local sourcing models.

Frequently Asked Questions

What is the main benefit of using premium padel turf?

Premium padel turf provides optimal ball bounce and reduces ankle strain significantly compared to regular concrete courts.

How do padel turf manufacturers ensure durability and long-term value?

Top factories use advanced polymer formulations and UV-stabilized fibers to extend the lifespan and wear resistance of padel turf surfaces.

What role does advanced fiber technology play in padel turf performance?

Advanced fiber technology ensures consistent playability across various climates by treating fibers with UV stabilizers and using frost-resistant polymer mixtures.

How do top manufacturers ensure global compliance and certification standards?

These manufacturers adhere to rules set by FIP, Spanish Padel Federation, USPA, and ISO requirements, ensuring optimal performance and safety.

What cost-efficiency benefits come from using high-quality padel turf?

High-quality turf reduces lifetime maintenance costs and saves water significantly due to its durable and eco-friendly design.

Table of Contents

- Superior Performance and Playing Experience from Premium Padel Turf

- Durability and Long-Term Value of Padel Turf from Industry-Leading Factories

- Innovation in Surface Technology and Infill Systems at Top Padel Turf Factories

- Global Compliance and Certification Standards in Padel Turf Manufacturing

- Cost-Efficiency, Sustainability, and Global Supply Chain Benefits

-

Frequently Asked Questions

- What is the main benefit of using premium padel turf?

- How do padel turf manufacturers ensure durability and long-term value?

- What role does advanced fiber technology play in padel turf performance?

- How do top manufacturers ensure global compliance and certification standards?

- What cost-efficiency benefits come from using high-quality padel turf?