Compliance with International Padel Federation (FIP) Standards

Understanding FIP Guidelines for Court Dimensions and Equipment Placement

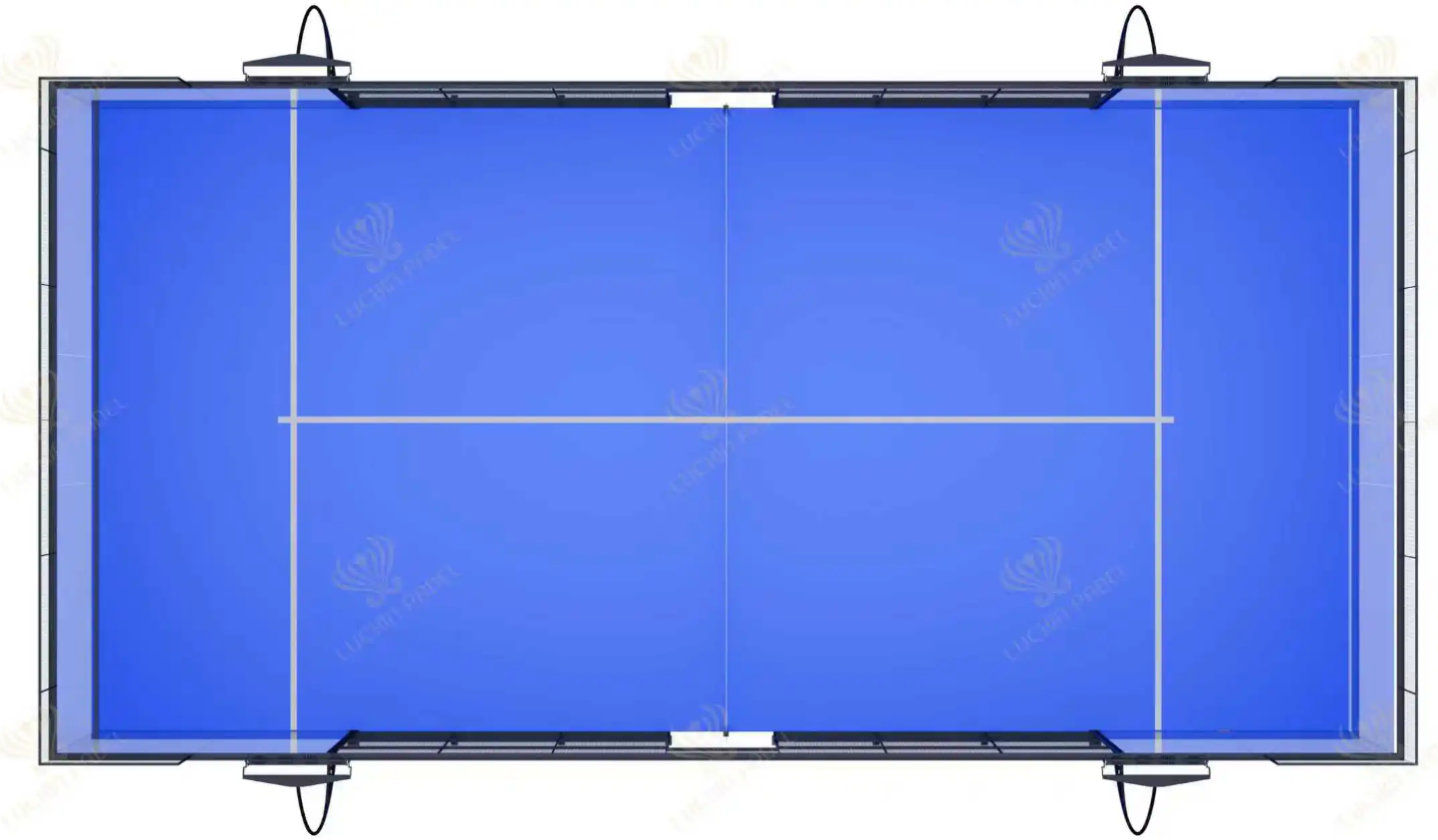

Top manufacturers of padel courts follow the design standards set by FIP, which includes a standard court size of 20 meters by 10 meters with a tolerance range of plus or minus 0.5%. The walls must be at least 3 meters high to maintain consistent ball bounce and proper player movement throughout all facilities worldwide. These rules were officially put into place back in 2023 by the International Padel Federation. They check everything against their technical manual that lists important dimensions like how high the net should be - 0.88 meters in the middle and 0.92 meters at the posts. Service lines need to be positioned exactly 6.95 meters away from the net according to these guidelines too. Such precise measurements help ensure fair play conditions no matter where someone plays padel around the globe.

Validating Padel Court Factory Layouts Against FIP Regulations

Third party inspectors these days rely on laser guided systems when they check production lines for any issues. They measure how much components such as tempered glass panels and galvanized steel frames deviate from specifications. Plants that manage to stay within 0.3% dimensional tolerance see about 62 fewer installation problems than those without certification. Before actual manufacturing starts, digital twin tech is being used increasingly to double check things like wall angles and where doors go against FIP's safety standards for collisions. This helps catch mistakes early and improves overall design precision across the board.

Manufacturer Responsibilities in Maintaining Global Quality Standards

Manufacturers who want their products certified need to get hold of FIP approved synthetic turf with at least 12mm pile height and 7500DTEX yarn. They also have to run those quarterly ISO 9001 audits specifically looking at welding processes and how well they handle corrosion protection. Plus there's all that paperwork needed showing the mesh fencing can survive 200 cycles of testing. Most pros know this stuff matters - around 78% of major tournaments insist on seeing EN 14620 compliance certificates before they'll even consider using the courts. And let's be honest, nobody wants to end up on the wrong side of FIP's books. Three failed quality checks in a row means getting booted off the approved suppliers list, which is why most serious players keep their operations pretty tight throughout the whole supply chain.

Material Selection and Durability Testing in Padel Court Factory Production

Galvanized Steel Quality and Corrosion Resistance per ISO and EN Standards

The best manufacturers of padel courts rely on hot dip galvanized steel that meets ISO 1461:2022 standards. They apply around 550 grams per square meter of zinc coating which really helps stop rust forming especially important for courts located near coasts or areas with lots of humidity. To check if they meet EN 10346 requirements, these companies run their products through rigorous salt spray tests lasting about 1,200 hours. What this shows is that corrosion stays well below 0.5 micrometers per year when tested in those special weathering chambers. And all this means the structures should last way beyond 25 years even with regular play in tropical climates where moisture is constantly present.

Performance Testing of Synthetic Turf Under Real-World Conditions

The robotic test rigs run through around 10,000 simulated player movements each year just to check out those important performance numbers. They look at things like how much the surface gives way vertically when someone steps on it (should be less than 7mm with 20kg pressure), what kind of twist resistance there is for stable footing between 25 and 50 Newton meters, and how well it absorbs shocks by cutting down energy impact somewhere between 55% and 70%. For outdoor turf products, we put them through their paces under UV lights too according to standards set by ISO 4892-3. After sitting under artificial sun for 3,000 hours in that Q-Lab machine from last year's tests, the fibers need to stay intact at least 85% of what they originally were.

Tempered Glass Safety and Impact Resistance Evaluations

Perimeter glass undergoes a three-stage quality process: thermal strengthening at 620°C followed by rapid cooling (EN 12150-1), fragmentation testing ensuring particles <1cm² and fewer than 80 per dm², and impact validation using 70kph ball strikes per FIP Regulation 4.2.5.

Seismic Zone Compliance: NTC2018 and Regional Construction Codes

In seismic zones with peak ground acceleration of 0.35g or higher, factories adapt steel frame designs using Eurocode 8 calculations. Connection plates are analyzed via finite element modeling to achieve safety factors above 3.0 against lateral forces, meeting Japan's BCJ 2016 and California's CBC 2022 earthquake standards.

Structural Safety Certification and Third-Party Validation

EN 1090 Certification for Steel Components in Padel Court Frames

The EN 1090 certification means structural steel parts actually comply with EXC2 standards when it comes to load-bearing frames. The process checks several key areas including how good the welds are according to ISO 5817-B standards, makes sure bolts are tightened within a 15% margin of error, and tests against corrosion using those salt spray methods from ISO 12944-2. What's interesting is that these frames need to handle loads that are about 72% greater than what they'd normally face in day to day operations. This requirement matches up with the durability standards established by CEN back in Europe, which helps explain why many construction projects across the continent specify this kind of certification.

CE Marking and Structural Integrity Assurance

The CE mark basically means a product meets requirements under the Construction Products Regulation regarding strength and structural integrity. Third party testers check several critical aspects including anchor points which must withstand at least 15 kilonewtons when pulled out. Glass supports need to pass EN 12600 standards withstanding impacts of around 100 joules, while structures should handle wind forces equivalent to speeds up to 140 kilometers per hour according to EN 1991-1-4 guidelines. For static loading tests, products undergo stress equal to 150 percent of what they're designed for during a full day's testing period. During this time, any bending or sagging shouldn't exceed one five-hundredth of the total span length from end to end.

Role of Independent Labs in Safety Verification

Reputable laboratories subject court components to 100,000+ stress cycles under ISO 20957-10, simulating 15 years of intensive play. Industry data from 2023 shows third-party validated courts last 40% longer than self-certified equivalents. Manufacturers that adopt continuous third-party audits reduce structural failure rates by 72%, according to sports facility safety reports.

In-Process Quality Assurance During Padel Court Manufacturing

Implementing ISO 9001 Standards for Consistent Factory Output

ISO 9001-certified quality management systems standardize operations from raw material intake to final assembly. Third-party audits confirm 98% adherence to dimensional tolerances for steel and glass components (Quality Digest, 2023), with corrective actions resolving non-conformities within 24 hours. This systematic control reduces batch inconsistencies by 40% compared to non-certified facilities.

In-Line Inspections to Prevent Defect Propagation

Automated vision systems perform real-time weld inspections at six critical stages, detecting issues such as porosity or misaligned brackets. Technicians validate flagged anomalies through tactile checks and load simulations. Facilities using this dual-layer inspection method report 92% fewer post-installation adjustments (Sports Surfacing Report, 2024).

Traceability Systems for Materials Across High-Volume Production

Factories today are using all sorts of tech to keep tabs on their materials. RFID tags help track where galvanized steel comes from, while barcode scanners make sure those turf rolls get assigned correctly to each workstation. And let's not forget about digital twins recording every detail of how glass gets tempered. All these gadgets really pay off when something goes wrong. When defects pop up, manufacturers can trace back problems much faster than before. The Manufacturing Journal reported last year that this approach cuts down wasted materials by around two thirds in big production runs. Every hour, workers compare what's actually happening on the factory floor with those FIP specs, ensuring everything meets the strict requirements needed for sports equipment performance standards.

Final Inspection, Compliance, and Long-Term Performance Validation

Pre-Shipment Visual and Functional Testing of All Court Elements

Each component undergoes a 38-point inspection covering dimensional accuracy (glass thickness ±0.5mm), structural loading (500 kg\/m²), and surface defects. According to the 2024 Court Manufacturing Report, automated optical inspection systems reduce shipping defects by 63% compared to manual evaluations.

On-Site Installation Simulations to Detect Design Flaws Early

Factories use scaled prototypes to replicate real-world assembly, identifying issues such as mismatched bolt patterns or drainage misalignments before mass production. One manufacturer reported saving $18,000 per court by eliminating on-site rework through early simulation.

Documentation and Certification Packages from Leading Padel Court Factories

Compliance packages include material traceability records, EN 1090 certificates for steel frames, and FIP-validated dimension reports. Over 92% of certified facilities now employ digital twin documentation systems to accelerate approvals for international clients.

Case Study: Reducing Field Failures by 40% Through Rigorous Final QA

A European factory achieved 14 months of failure-free operation by implementing pre-shipment vibration testing (simulating magnitude 8.0 earthquakes) and humidity cycling for coastal installations. Its ISO 17025-accredited QA process has become an industry benchmark for long-term reliability.

FAQ Section

What are the standard dimensions for a padel court according to FIP?

The standard dimensions for a padel court as per FIP guidelines are 20 meters in length and 10 meters in width, with a tolerance of plus or minus 0.5%.

What materials are required for an FIP-certified padel court?

For FIP certification, courts need to use approved synthetic turf with at least a 12mm pile height and hot dip galvanized steel frames meeting specific ISO and EN standards.

Why are digital twin technologies used in padel court manufacturing?

Digital twin technologies are used to ensure precise measurements and catch design errors early by simulating court components against FIP's safety and collision standards.

How does CE Marking assure the quality of padel courts?

CE Marking ensures that padel courts meet requirements regarding strength and structural integrity, with several critical aspects checked by third-party testers for compliance.

Table of Contents

- Compliance with International Padel Federation (FIP) Standards

- Material Selection and Durability Testing in Padel Court Factory Production

- Structural Safety Certification and Third-Party Validation

- In-Process Quality Assurance During Padel Court Manufacturing

- Final Inspection, Compliance, and Long-Term Performance Validation

- FAQ Section