Customized Design and Planning for Professional Padel Courts

Understanding padel court dimensions and layout standards for optimal gameplay

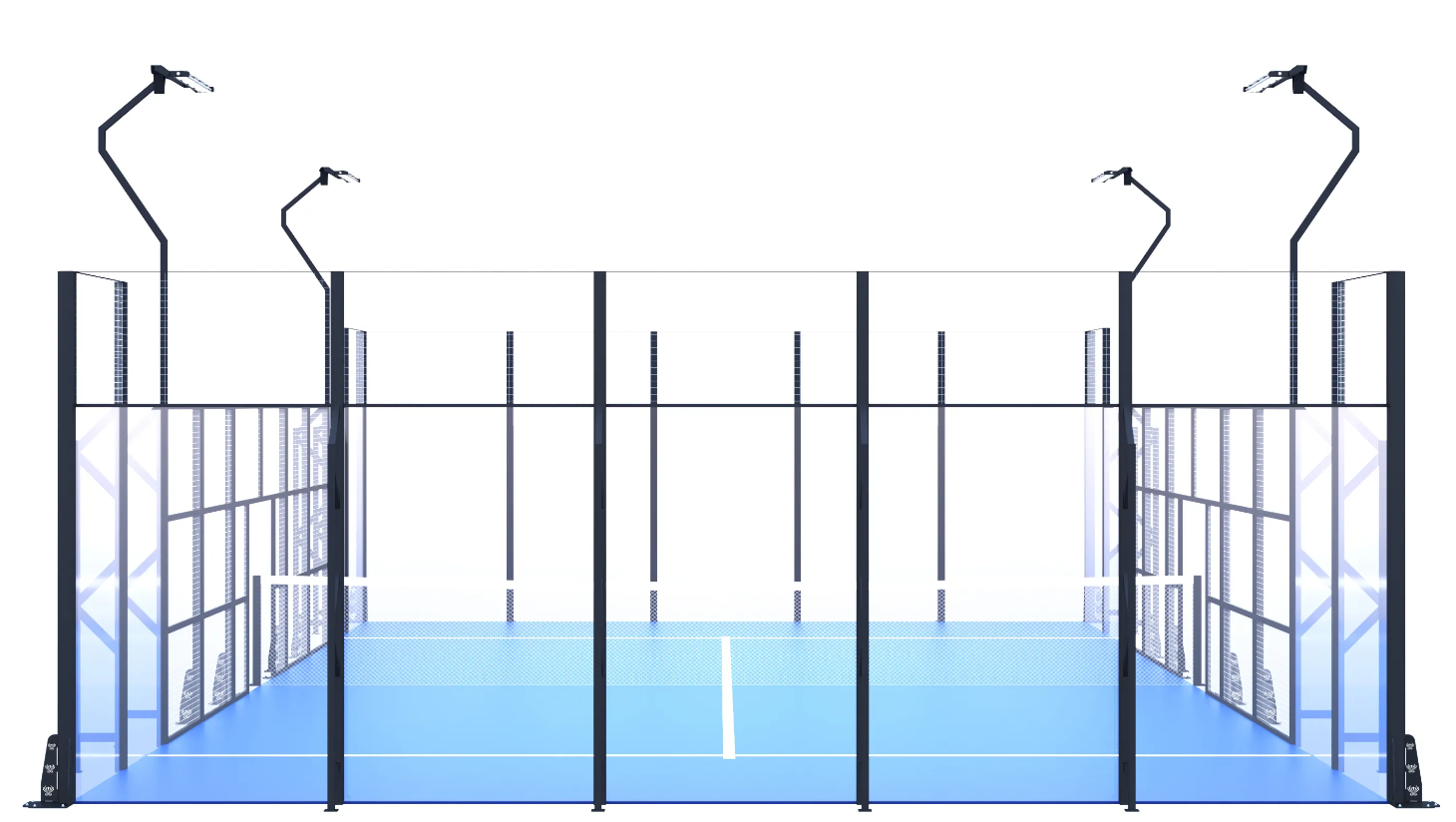

For professional padel play, courts need to follow FIP regulations measuring about 20 meters long by 10 meters wide. They also require glass walls around 4 meters high and safety areas extending at least 3 meters beyond each side. When building these courts, manufacturers look closely at local conditions too. Factories analyze how wind might affect gameplay or if ground slopes could create problems during matches. Studies show something interesting here too. Courts constructed with measurements accurate within plus or minus 2 centimeters actually cut down on player injuries by roughly 18 percent according to research published in the Sports Engineering Journal last year. Getting those dimensions right matters for both performance and safety reasons.

Tailoring court designs to site-specific and client requirements

Sloped terrains require elevated foundations, while urban spaces benefit from modular fencing systems adaptable to irregular footprints. Leading manufacturers use parametric modeling to ensure 96% of available space meets FIP clearance rules without compromising spectator sightlines.

Integrating technical specifications early in the design phase

Prioritizing drainage slope (1–2%), LED lighting placement, and subsurface compaction during planning eliminates 73% of post-construction modifications. Advanced factories employ BIM software to simulate ball trajectories across 15 lighting scenarios, aligning structural supports to minimize shadows.

Balancing aesthetic appeal with functional performance in court layouts

Color-contrasted lines improve player visibility, while matte-finish glass reduces glare by 40% compared to standard surfaces. Custom branding panels withstand 200kg impacts, combining corporate identity with safety–key to achieving 89% client satisfaction in hospitality installations.

High-Performance Materials and Advanced Construction Techniques

Premium materials: Steel frameworks, tempered glass, and durable fencing systems

The steel framework can hold loads above 1,500 kg per square meter and stands up to corrosion thanks to hot dip galvanization treatment. When it comes to tempered glass walls, we're talking about panels between 4 to 6 millimeters thick that satisfy FIP standards both for how balls bounce off them and what people can see through. These glasses have surface compression strength well beyond 300 MPa which means they really fight back against cracks forming. For fencing, aircraft grade aluminum at 3 to 5 mm thickness delivers impressive specs too – around 400 Newtons per square millimeter tensile strength while weighing in 30% less than regular alternatives. And let's not forget those UV stabilized polycarbonate panels that keep letting in 92% of available light even after being exposed to sunlight equivalent to 10,000 hours straight. That kind of durability makes all the difference in real world conditions.

Artificial grass surfaces: Durability, ball response, and low maintenance

Polyethylene artificial turf with 12–15mm pile height reduces player fatigue by 18% compared to traditional surfaces and maintains <0.8λ vertical ball bounce deviation (2024 Padel Surface Study). Sand-filled hybrid turf systems show 30% slower fiber wear in accelerated testing (ISO 4919:2023), supported by drainage layers handling 120L/m²/hour to prevent waterlogging.

Comparing surface options for long-term resilience and playability

Acrylic surfaces offer 40% higher midsole abrasion resistance ideal for clay-style play, while polypropylene systems enable 0.25-second faster directional changes in competitive matches (ITF Padel Commission 2023).

Innovative modular construction and precision assembly methods

Laser-aligned modular components allow 14-day installation via interlocking joints accurate to ±0.5mm. Automated tensioning ensures 50 N/m² glass panel uniformity–exceeding FIP’s 45 N/m² requirement for tournaments.

End-to-End Project Management from Site Assessment to Installation

Client consultation and on-site evaluation by the padel court factory

Manufacturers begin with a detailed needs assessment and site inspection, evaluating soil conditions, drainage, and spatial constraints. This ensures alignment with International Padel Federation (FIP) guidelines and accounts for local climate factors.

Streamlined construction process: Foundation to final installation

Projects follow a phased sequence: land preparation, reinforced concrete foundations, modular enclosure assembly, and surface installation. Laser-guided systems ensure millimeter-perfect alignment of glass walls and fencing, using weather-resistant materials to avoid delays.

Precision in enclosure alignment and structural integrity checks

Post-construction inspections verify eight critical parameters:

- Glass panel deflection under load (δ±3mm)

- Fence mesh tension consistency (±5% tolerance)

- Surface flatness (δ±2mm/m² variance)

- Anchor bolt torque specifications (110–130 Nm)

Post-installation support, maintenance training, and warranty services

Factories provide comprehensive operational guides covering daily upkeep, seasonal care, and emergency repairs. Most offer 10-year structural warranties and 5-year surface guarantees, with remote diagnostics resolving 83% of issues without on-site visits (Sports Facility Management Report 2024). This turnkey approach delivers FIP-certified venues in 6–8 weeks–37% faster than traditional builds.

Compliance with FIP Standards and Certification for Tournament-Ready Courts

Why adherence to FIP regulations is essential for professional venues

Uncertified courts cannot host official competitions, limiting player development and revenue potential. Facilities aiming for tournament accreditation must comply with FIP’s exacting standards for dimensions, materials, and safety. For example, glass walls below 3m or deviations from the 10m × 20m footprint disqualify venues from hosting league matches.

Designing courts to meet international competition requirements

FIP-certified padel court factories focus on three core areas:

- Boundary systems: 4m tempered glass walls with UV-resistant coatings to prevent warping

- Playing surfaces: Shock-absorbent artificial turf with δ±3mm grain height for consistent ball bounce

- Lighting: Minimum 500 lux illumination free of glare

These features support global tournament compatibility and cut long-term maintenance costs by 18% compared to non-standardized designs (2023 court operator survey).

Third-party inspections and certification processes for quality assurance

The best manufacturers work alongside outside auditors to check things are done right during key points in construction - when pouring the foundation, installing enclosures, and doing surface tests at the end. Courts that get certified go through more than 70 different quality checks throughout their development. They test how balls bounce back after hitting the surface and run stress tests on the structure itself. All these checks help avoid expensive fixes later on. Most projects following FIP standards actually open for business around eight weeks after breaking ground, which is pretty impressive considering all the testing involved. About 9 out of 10 such projects make it to this stage without major delays.

Enclosure Systems and Client-Centric Selection Criteria

Glass, Mesh Fencing, and Stepped Walls: Performance, Safety, and Visibility

Modern enclosures balance functionality and spectator experience. Tempered glass (4–6mm) provides 92% optical clarity and reliable ball rebound. Mesh fencing lowers upfront costs by 15–20% (SportsVenueTech 2022) and improves airflow but requires quarterly tension checks. Stepped wall systems enhance sound dampening, reducing ambient noise by 8–12 decibels versus flat designs.

| Material | Ball Rebound Accuracy | Maintenance Frequency | Visibility Score (1-10) |

|---|---|---|---|

| Tempered Glass | 98% | Annual | 9.7 |

| Polyethylene Mesh | 89% | Quarterly | 6.2 |

| Stepped Composite | 94% | Biannual | 8.1 |

Optimizing Acoustics and Ball Rebound Through Strategic Enclosure Design

When it comes to predicting how sound behaves in spaces, parametric modeling really shines. Cities have seen noise levels drop anywhere from 85 to 90 percent thanks to these models guiding design decisions. Take those angled glass panels we've been talking about lately - tilting them just right at around 3 to 5 degrees makes a world of difference. Not only does this setup keep balls moving predictably across surfaces, but it also cuts down on annoying echoes by nearly two thirds when compared with flat glass arrangements. And let's face it, working hand in hand with acoustics experts is pretty much essential nowadays. Indoor sports facilities especially need this expertise since reflections inside can get up to 40 percent worse than what happens outdoors on open courts. Makes sense when you think about all those hard surfaces bouncing sounds back and forth without any natural dampening effects.

Key Factors in Choosing a Reliable Padel Court Factory and Manufacturer

Select partners who provide full lifecycle documentation; 78% of facility managers view 10-year structural warranties as essential (GlobalSportsInfra 2023). Confirm FIP-recognized certifications and request 3D renderings early in the design phase. Top providers combine modular construction expertise with on-site adaptability, cutting installation time by 30% while maintaining precise enclosure alignment.

Evaluating Sustainability, Cost-Efficiency, and Long-Term Value

Fencing made from recycled polyethylene containing around 85% post-industrial material actually works just as well as new plastic options while costing about 18% less over its entire lifespan. When facilities install solar ready frameworks, they typically save somewhere between $1,200 to maybe even $1,800 every year on electricity bills for lighting those outdoor sports areas. The latest Sports Facility Sustainability Report from 2023 shows something interesting too. Courts built with these green optimizations tend to pay for themselves in about seven years time. That's three whole years quicker compared to regular construction methods mainly because there are roughly 23% fewer maintenance costs involved plus various tax breaks that make things even better financially speaking.

FAQ Section

What are the standard dimensions for a professional padel court?

Professional padel courts must follow FIP regulations, measuring approximately 20 meters long by 10 meters wide with 4-meter high glass walls and safety areas extending at least 3 meters beyond each side.

Why are FIP regulations important for padel courts?

FIP regulations are crucial as uncertified courts cannot host official competitions, which limits player development and revenue potential. Compliance ensures venues are eligible for tournament accreditation.

What are the benefits of using premium materials in padel court construction?

Premium materials like steel frameworks, tempered glass, and durable fencing systems offer superior load capacity and resistance to environmental factors, ensuring longevity and high performance in various conditions.

How does artificial grass improve padel court gameplay?

Artificial grass surfaces reduce player fatigue, maintain vertical ball bounce consistency, and offer low maintenance compared to traditional surfaces, enhancing gameplay quality.

What practices ensure efficient padel court construction?

Efficient construction includes phased processes like land preparation, precise enclosure alignment, and uniform glass panel tensioning. Use of laser-guided systems and weather-resistant materials helps avoid delays.

Table of Contents

- Customized Design and Planning for Professional Padel Courts

- High-Performance Materials and Advanced Construction Techniques

- End-to-End Project Management from Site Assessment to Installation

- Compliance with FIP Standards and Certification for Tournament-Ready Courts

- Enclosure Systems and Client-Centric Selection Criteria

-

FAQ Section

- What are the standard dimensions for a professional padel court?

- Why are FIP regulations important for padel courts?

- What are the benefits of using premium materials in padel court construction?

- How does artificial grass improve padel court gameplay?

- What practices ensure efficient padel court construction?