Why China Dominates the Global Padel Court Manufacturing Market

Global Surge in Padel Popularity Driving Demand for Padel Court China Solutions

Global spending on padel courts hit around $400 million last year, and experts expect this number to grow at about 6.5% each year until 2030. Why? More people are getting into sports tourism and clubs are popping up everywhere. Most of these new courts actually come from Chinese factories which now handle well over half the world's padel equipment needs. Their ability to mass produce has kept pace with what seems like endless demand. The sport is taking off fast in places like Europe, Latin America, and several developing countries too. For instance, installing courts using Chinese materials can cut construction costs anywhere from 30% to 40% when compared to building them locally. That kind of price difference explains why so many operators are turning to Asian suppliers despite concerns about quality control sometimes.

China’s Competitive Advantages in Padel Infrastructure Production

Three key factors underpin China’s dominance:

- Integrated supply chains for tempered glass, galvanized steel, and UV-resistant turf—produced domestically at 20–35% lower costs

- Advanced manufacturing capabilities enabling rapid prototyping and high-volume output (5,000+ courts annually)

- Streamlined logistics networks that cut lead times for European clients by 3–4 weeks versus regional suppliers

A 2024 regional market analysis highlights how China’s industrial ecosystem supports 78% of Asia-Pacific’s padel court exports, with ISO 9001-certified factories ensuring precision in large-scale orders.

Case Study: Spanish-Inspired Padel Expansion Enabled by Chinese Manufacturers

Spain started building over 500 padel courts across the country from 2021 to 2023, and Chinese manufacturers stepped in with ready-made systems that met all FIAP standards while costing about 22 percent less than what European companies would charge. These Chinese suppliers proved they could offer good prices without sacrificing quality, which made their padel court kits popular among cities looking to expand facilities without breaking budgets. Since then, at least 17 different nations have started buying similar Chinese solutions for their own padel court projects. Countries in Latin America and parts of Africa especially saw how Spain's success story worked, and now many are following suit as they try to grow padel participation around the world.

Core Materials and Build Standards of High-Quality Padel Court China Systems

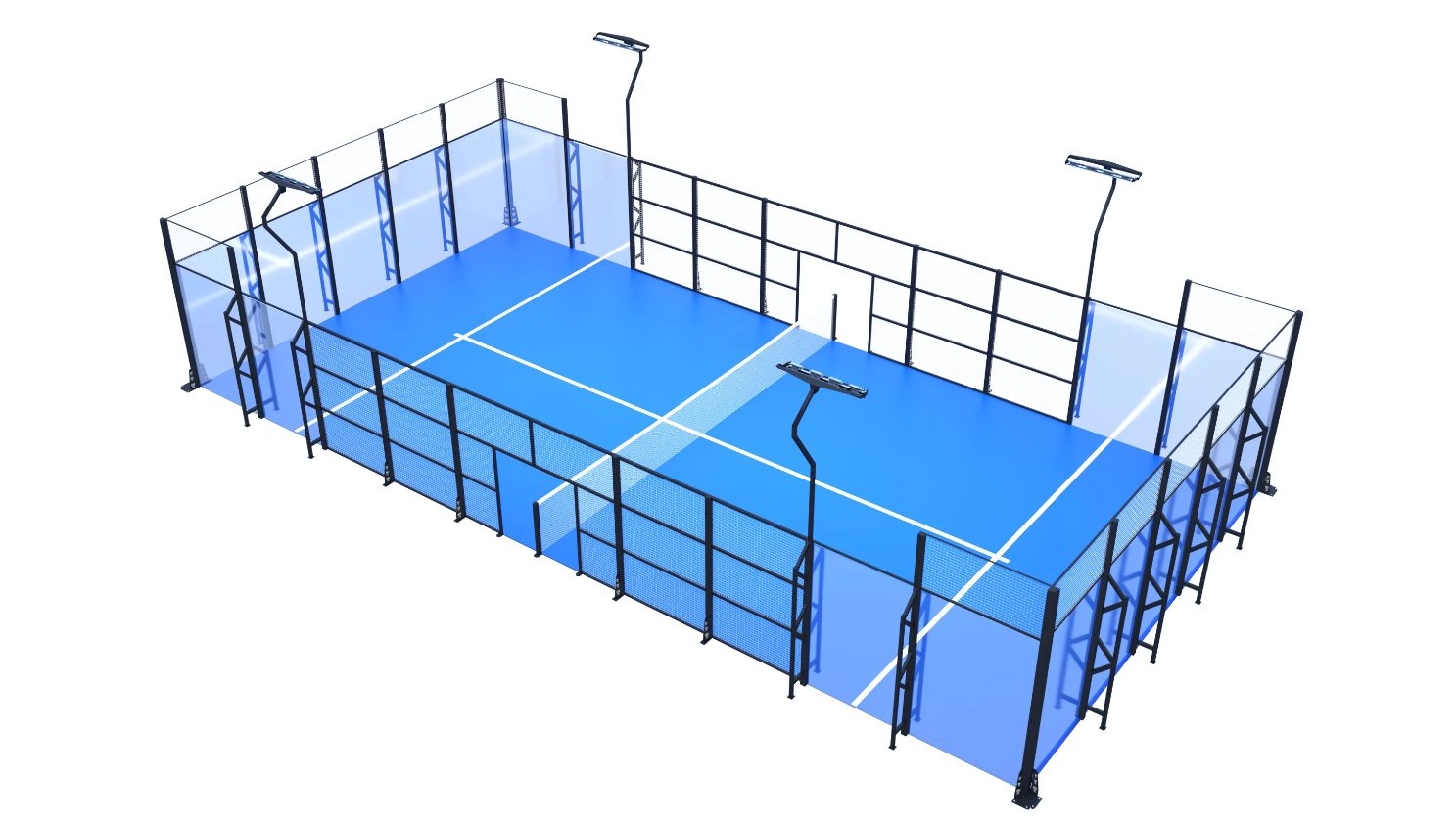

Chinese manufacturers combine advanced engineering with rigorously tested materials to deliver padel courts meeting international performance standards. Three critical components form the foundation: reinforced steel frames, tempered safety glass, and UV-resistant artificial turf. These elements ensure durability, safety, and consistent playability across diverse climates and usage levels.

Essential Components: Artificial Turf, Tempered Glass, and Steel Frames from China

Galvanized steel frames compliant with GB/T 2518-2008 maintain structural integrity under temperature extremes. Tempered glass walls exceeding 12mm thickness resist shattering during intense gameplay. Polyethylene-based turf with a 20mm pile height ensures optimal ball bounce and player traction, meeting FIFA Quality certification benchmarks. Together, these materials support 8+ hours of daily use in commercial settings.

Material Selection Criteria: Balancing Performance and Cost in Padel Court China Units

Climate conditions shape material choices—coastal installations require salt-resistant galvanization (600g/m² zinc coating), while arid regions benefit from turf with enhanced UV stabilizers. Budget-focused operators may opt for polyethylene/nylon hybrid turf, which is 30% cheaper than full-nylon variants, though elite venues typically choose FIFA-certified surfaces. Modular steel designs also reduce shipping costs compared to welded structures.

Innovations in Durability and Sustainability: Eco-Friendly Surfaces and Modular Design

Recent advancements include: - Turf backing made from 65% recycled rubber - Rapid-install modular systems allowing court relocation within 72 hours - Solar-reflective glass coatings reducing indoor cooling needs by 18% Leading factories hold ISO 14001 environmental certifications, achieving up to 92% material recycling rates in production.

Trade-Off Analysis: Mass Production vs. Quality Consistency in Padel Court China Output

High-volume producers gain 15% cost advantages through automated welding and bulk purchasing. However, premium suppliers enforce tighter tolerances—glass panel variation ≤0.5mm versus 2mm in budget lines. Third-party audits show 84% of GB/T-certified manufacturers pass ISO 9001 quality checks on first inspection, compared to just 53% of uncertified peers.

How to Verify Reliability and Certifications of Padel Court China Suppliers

As global demand grows, verifying supplier credibility is essential when sourcing padel court China systems. Over 70% of qualified manufacturers now hold ISO 9001 for quality management and ISO 14001 for environmental responsibility (Global Sports Infrastructure Report 2024). For European markets, compliance with EN 15367 safety standards for sports surfaces is standard; North American buyers should prioritize ASTM F2772 certification for shock absorption and surface consistency.

Key Certifications and Compliance Standards for Padel Court China Manufacturers

Third-party verification ensures adherence to international benchmarks. Artificial turf suppliers must provide SGS test reports showing less than 5% fiber loss after 50,000 abrasion cycles. Tempered glass panels require documented impact resistance exceeding 1,500 N/m². Always validate certificates directly with issuing bodies like TÜV Rheinland to avoid forged documentation—a known issue among less than 10% of unverified suppliers (Sports Facility Safety Council 2023).

Assessing Quality Control Processes in High-Output Chinese Production Facilities

Top-tier factories employ automated optical inspection (AOI) systems that detect substandard welds in steel frames with 99.7% accuracy. During due diligence, request video audits showcasing real-time measurements of turf backing thickness (minimum 1.2mm) and climate-controlled storage for glass components. Suppliers managing over 500 annual installations typically maintain defect rates below 0.8% using statistical process control.

Red Flags and Best Practices in Supplier Reliability Evaluation

Avoid manufacturers that: - Cannot produce original material test reports - Provide generic "pass" certificates without product-specific data - Decline third-party inspections Buyers following QCAdvisor’s factory audit guidelines recommend pre-shipment checks covering joint reinforcement, glass edge smoothness, and UV stabilizer concentration in synthetic fibers. Conduct lab testing on material samples before committing to bulk orders—leading manufacturers offer free test units backed by 98% specification match guarantees (Padel Material Association 2023).

Turnkey Padel Court China Solutions: From Custom Design to On-Site Installation

Full-Service Offerings: How Chinese Suppliers Deliver Complete Padel Court Projects

Leading padel court China manufacturers now provide end-to-end solutions—from concept to commissioning. Integrated teams of engineers, material scientists, and installation experts streamline delivery into three phases: - Customized Design: CAD modeling tailors court dimensions, branding, and lighting to client needs - Material Optimization: AI tools match regional climates with suitable composites for turf, glass, and steel - Turnkey Installation: Certified crews handle foundation work to final calibration, reducing client oversight by 78% compared to fragmented procurement models.

Indoor vs Outdoor Court Customization Options from Padel Court China Providers

Climate dictates design priorities. Indoor courts feature: - UV-resistant glass (3.2x thicker than standard) - Shock-absorbing rubber bases for multi-level buildings Outdoor configurations emphasize: - Saltwater-resistant steel frames compliant with ISO 9227 corrosion standards - Permeable artificial turf with 15L/m² drainage capacity to prevent pooling

Permanent vs Temporary Installation Flexibility in Modern Chinese Systems

Modular engineering allows 83% of components to serve dual applications:

| Installation Type | Key Features | Typical Deployment Timeline |

|---|---|---|

| Permanent | Concrete anchors, welded joints | 12–16 weeks |

| Semi-permanent | Bolt-fastened base plates | 6–8 weeks |

| Temporary | Interlocking panels with ballast | 48-hour setup |

This adaptability supports pop-up urban courts and permanent Olympic-grade complexes alike.

Design Trends: Aesthetic and Functional Innovations in Padel Court China Builds

According to the 2024 Global Padel Report, 41% of premium installations now blend Spanish design heritage with Asian efficiency through: - Gradient-colored glass walls reducing glare by 62% - Recessed LED arrays enabling broadcast-ready illumination - Recycled polymer turf meeting FIFA Quality Pro standards at 34% lower cost Seamless extrusion techniques have eliminated 92% of welding seams, delivering cleaner aesthetics without compromising strength.

Strategic Sourcing Guide: Choosing the Right Padel Court Manufacturer in China

Step-by-Step Process to Identify Proven Padel Court China Suppliers

When looking for suppliers, start checking what they specialize in when it comes to sports infrastructure stuff. Give extra attention to companies that have been working specifically with padel courts for at least five years or so. Location matters too - most Chinese sports facility makers are actually based in Guangdong and Zhejiang provinces, which together account for around 40-45% according to last year's Global Infrastructure Report. The numbers aren't exact but give a good general idea. For real confidence in their capabilities, go with vendors who show CAD drawings upfront and share material test results during initial talks. Seeing this kind of documentation right from the beginning is pretty much essential if we want to ensure they know what they're doing technically speaking.

Supplier Vetting Techniques: Site Visits, References, and Sample Testing

Conduct unannounced factory audits to assess welding precision and UV resistance in turf. Request 3–5 references from clients in similar climates to verify long-term durability. Independently test glass thickness (minimum 10mm tempered) and frame load capacity (≥2,500 kg/m²) to mitigate structural risks. Disqualify suppliers failing two consecutive quality inspections.

Market Data Insight: Over 60% of International Padel Facilities Use Components from China

This leadership stems from China’s optimized supply chains, cutting production costs by 20–35% versus European counterparts while maintaining FIVB/ITF compliance. Modular designs enable 30% faster deployment than traditional construction methods.

Long-Term Partnership Strategies with Padel Court China Manufacturers

Explore joint R&D initiatives to co-develop weather-resistant coatings or noise-dampening glass. Leading suppliers now offer AI-powered maintenance tracking, improving facility uptime by 18% through predictive part replacement. Negotiate flexible MOQs with tiered pricing to support phased rollouts and pilot projects.

FAQ

Why is China a major player in the global padel court manufacturing market?

China dominates the global padel market due to its integrated supply chains, advanced manufacturing capabilities, and streamlined logistics. This allows them to produce high-quality courts at lower costs compared to regional suppliers.

What materials are used in high-quality padel courts from China?

The core materials include reinforced steel frames, tempered safety glass, and UV-resistant artificial turf. These materials ensure durability and consistent performance.

How can one ensure the reliability of a padel court supplier in China?

Verify supplier reliability by checking their ISO certifications, conducting site visits, and requesting documentation like CAD drawings and material test results.

What are the benefits of using Chinese padel court solutions?

Chinese padel court solutions offer cost advantages, faster deployment, and high-quality standards. They are widely used in international facilities due to their efficiency and affordability.

Table of Contents

- Why China Dominates the Global Padel Court Manufacturing Market

-

Core Materials and Build Standards of High-Quality Padel Court China Systems

- Essential Components: Artificial Turf, Tempered Glass, and Steel Frames from China

- Material Selection Criteria: Balancing Performance and Cost in Padel Court China Units

- Innovations in Durability and Sustainability: Eco-Friendly Surfaces and Modular Design

- Trade-Off Analysis: Mass Production vs. Quality Consistency in Padel Court China Output

- How to Verify Reliability and Certifications of Padel Court China Suppliers

-

Turnkey Padel Court China Solutions: From Custom Design to On-Site Installation

- Full-Service Offerings: How Chinese Suppliers Deliver Complete Padel Court Projects

- Indoor vs Outdoor Court Customization Options from Padel Court China Providers

- Permanent vs Temporary Installation Flexibility in Modern Chinese Systems

- Design Trends: Aesthetic and Functional Innovations in Padel Court China Builds

-

Strategic Sourcing Guide: Choosing the Right Padel Court Manufacturer in China

- Step-by-Step Process to Identify Proven Padel Court China Suppliers

- Supplier Vetting Techniques: Site Visits, References, and Sample Testing

- Market Data Insight: Over 60% of International Padel Facilities Use Components from China

- Long-Term Partnership Strategies with Padel Court China Manufacturers

- FAQ